Key Factors to Consider When Choosing a Can Sealing Machine

When it comes to running a successful soda can line, one of the most important pieces of equipment you’ll need is a can sealing machine. This machine is responsible for sealing the cans after they have been filled with soda, ensuring that the product remains fresh and carbonated until it reaches the consumer. With so many different options available on the market, choosing the best can sealing machine for your soda can line can be a daunting task. However, by considering a few key factors, you can make an informed decision that will meet the needs of your production line.

One of the first factors to consider when choosing a can sealing machine is the speed at which it can operate. The speed of the machine will determine how many cans it can seal per minute, which is crucial for meeting production demands. If your soda can line operates at a high volume, you’ll want to choose a machine that can keep up with the pace of your production. On the other hand, if your production volume is lower, you may be able to get by with a slower machine.

In addition to speed, you’ll also want to consider the size and type of cans that the machine can seal. Some machines are designed to seal standard-sized soda cans, while others can accommodate larger or smaller cans. Make sure to choose a machine that is compatible with the cans you use in your production line to ensure a proper seal every time.

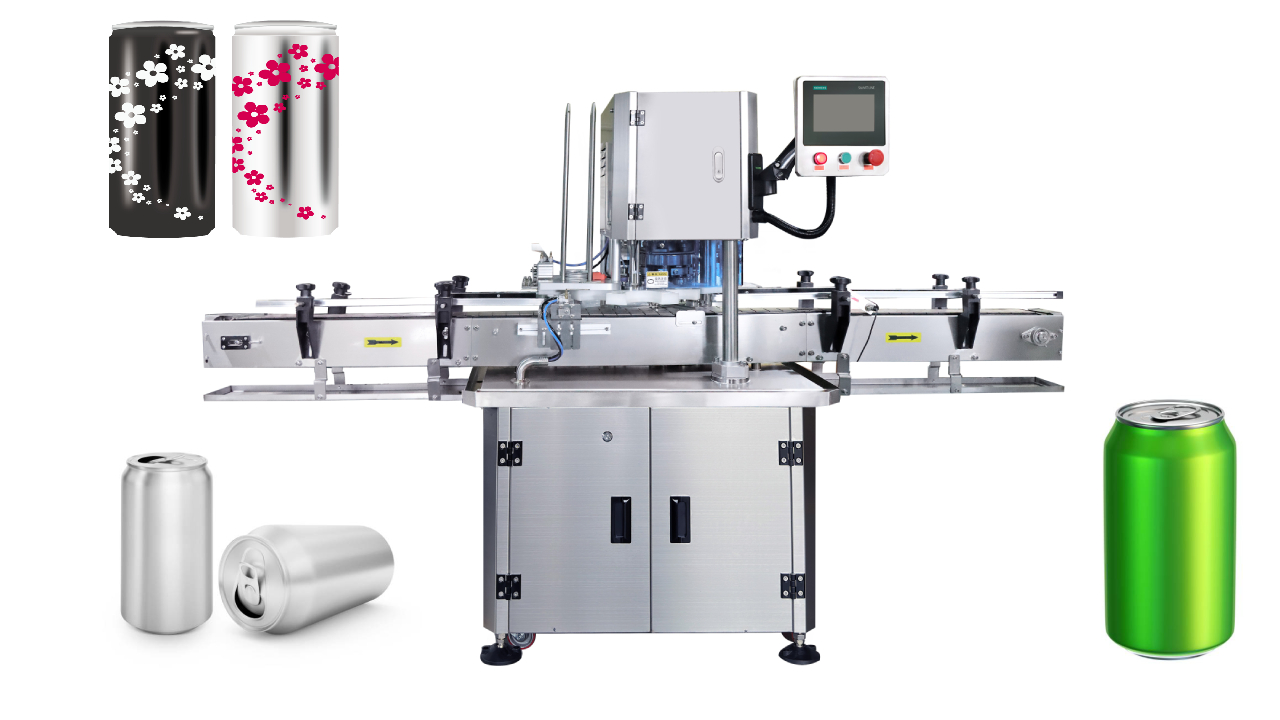

Another important factor to consider is the type of sealing method used by the machine. There are two main types of can sealing machines: rotary and linear. Rotary machines use a spinning head to seal the cans, while linear machines use a straight-line motion. Each type of machine has its own advantages and disadvantages, so it’s important to choose the one that best fits your production needs.

When choosing a can sealing machine, it’s also important to consider the level of automation that is required. Some machines are fully automated, meaning they can operate without any human intervention. Others require manual loading and unloading of the cans. If you’re looking to streamline your production process and reduce labor costs, you may want to opt for a fully automated machine. However, if you have a smaller operation or prefer more control over the sealing process, a semi-automated machine may be a better fit.

Finally, it’s important to consider the overall quality and reliability of the can sealing machine. Look for a machine that is made from durable materials and has a reputation for consistent performance. You’ll want a machine that can withstand the rigors of daily use and provide a reliable seal every time. Additionally, consider the level of customer support and service offered by the manufacturer, as this can be crucial in ensuring that your machine operates smoothly and efficiently.

In conclusion, choosing the best can sealing machine for your soda can line requires careful consideration of several key factors. By evaluating the speed, size, sealing method, automation level, and overall quality of the machine, you can make an informed decision that will meet the needs of your production line. With the right can sealing machine in place, you can ensure that your soda cans are sealed properly and efficiently, helping to maintain the quality and freshness of your product for consumers to enjoy.