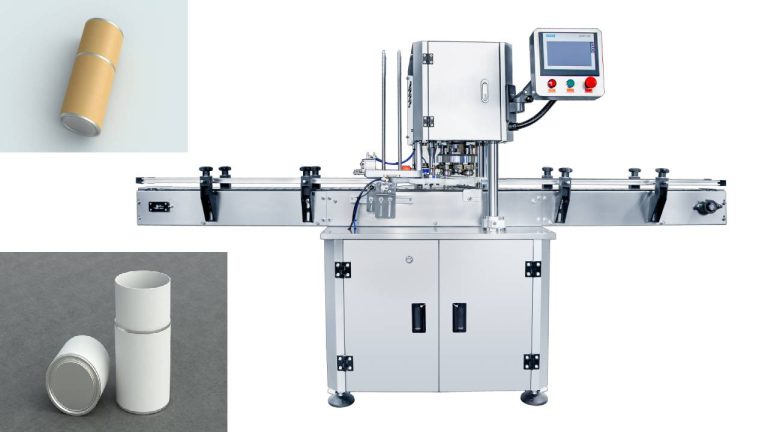

In the world of ghee packaging, the automatic ghee bottle vacuum capping machine has become an indispensable tool.

This machine is specifically designed to create a vacuum seal on ghee bottles, offering several significant benefits. By removing the air from inside the bottle before capping, it helps to extend the shelf life of the ghee. Air exposure can lead to oxidation and spoilage, but the vacuum seal prevents this, ensuring the ghee remains fresh and flavorful for longer periods.

The automatic operation of this machine ensures consistent and precise capping every time. It eliminates the possibility of human error and variations in the sealing process, guaranteeing that each bottle is properly sealed. This not only protects the quality of the ghee but also enhances the overall appearance and professionalism of the packaging.

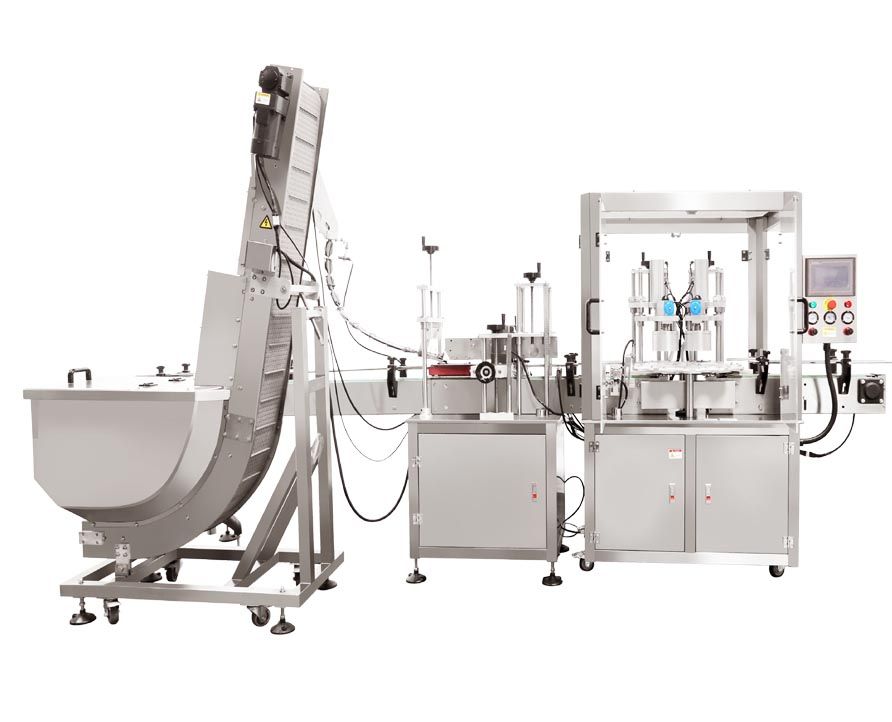

The speed and efficiency of the automatic ghee bottle vacuum capping machine are remarkable. It can handle a large number of bottles in a short amount of time, meeting the demands of high-volume production. This helps manufacturers keep up with market demand and deliver their products promptly.

The machine is also highly adjustable to accommodate different bottle sizes and shapes, providing flexibility for producers. It can be easily integrated into existing packaging lines, streamlining the entire process and improving productivity.

In terms of maintenance, it is designed for durability and ease of servicing. Regular upkeep ensures its smooth operation and longevity, minimizing downtime and maximizing the return on investment.

Overall, the automatic ghee bottle vacuum capping machine is a game-changer in the ghee packaging industry, offering superior preservation, efficiency, and quality control.

Stay tuned to our blogs for more in-depth coverage of the latest advancements in packaging technology for the food industry!