Servo twist-off capping systems are driven by advanced technologies that play a crucial role in their efficient and precise operation.

At the core of these systems is the servo motor technology. Servo motors provide highly accurate control of rotational speed and torque, allowing for precise application of the twisting force needed to secure the caps.

Precision sensors are incorporated to monitor various parameters such as cap position, torque applied, and rotational speed. This real-time feedback enables the system to make instant adjustments for optimal capping results.

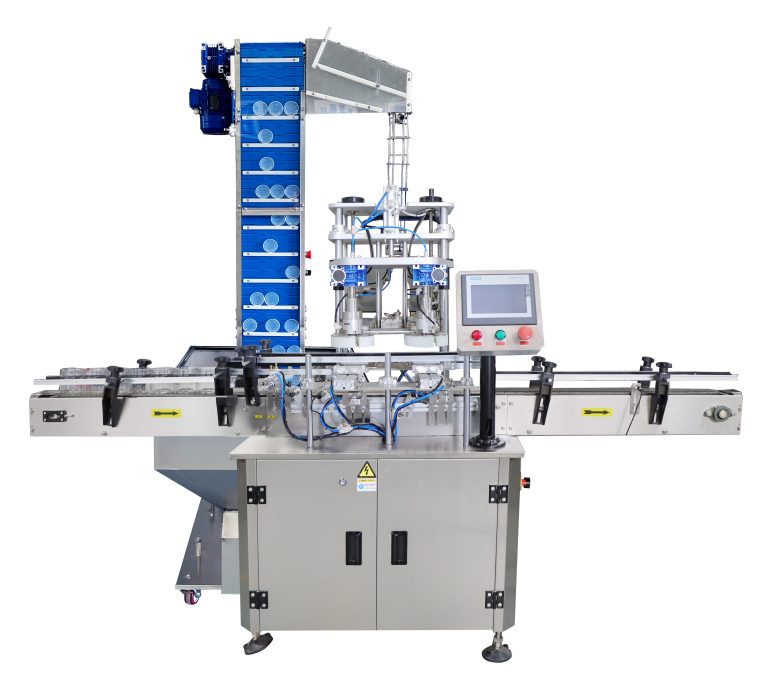

The control algorithms and software integrated into the system manage the complex sequence of operations. They ensure smooth coordination between different components, such as the cap feeding mechanism, the capping head, and the motor drive.

Advanced mechanical designs ensure stability and durability. Components are engineered to withstand the repetitive forces and motions involved in the capping process, minimizing wear and tear.

Materials used in the construction of the capping systems are selected for their strength, durability, and resistance to corrosion and wear. This ensures long-term reliable performance.

The integration of communication protocols allows the servo twist-off capping systems to interface with other equipment on the production line, facilitating seamless operation and centralized control.

In conclusion, the technology behind servo twist-off capping systems is a combination of precise motor control, intelligent sensing, advanced software, and robust mechanical and material engineering. Understanding these elements is key to appreciating the sophistication and effectiveness of these systems in modern packaging operations.