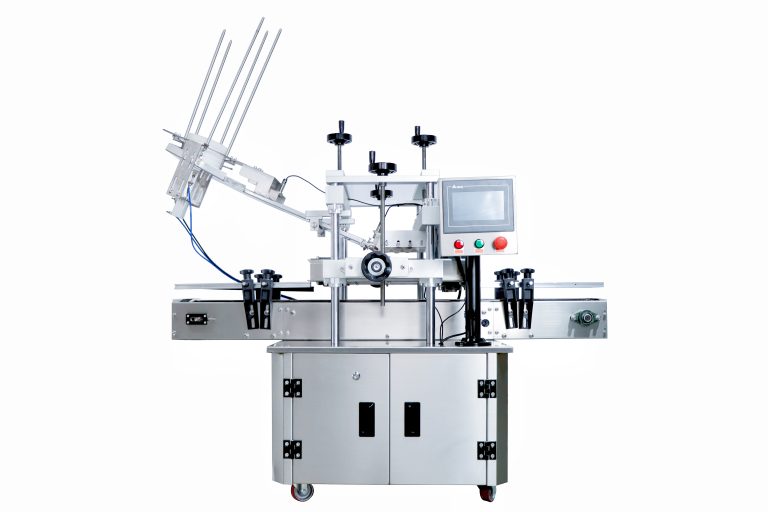

Automatic round bottle labelers have emerged as a revolutionary force in packaging lines for several compelling reasons.

Firstly, they bring an unprecedented level of efficiency and speed. These machines can label a large number of round bottles in a fraction of the time it would take with manual methods, significantly boosting the throughput of the packaging line.

The precision and accuracy they offer are unparalleled. Every label is placed precisely and consistently, ensuring a professional and uniform appearance. This not only enhances the aesthetic appeal of the packaged products but also reduces the chances of errors or mislabeling.

They are highly adaptable and can handle various bottle sizes, shapes, and label designs with ease. This flexibility allows for seamless integration into diverse packaging operations without the need for frequent adjustments or reconfigurations.

The consistent quality output of automatic labelers helps build and maintain brand reputation. Consumers are more likely to trust products with neatly and accurately labeled packaging.

Furthermore, they minimize human intervention, reducing the potential for human error and fatigue. This leads to fewer production delays and higher overall productivity.

Automatic round bottle labelers also contribute to cost savings in the long run. They reduce labor costs, minimize material waste due to accurate labeling, and require less maintenance compared to traditional labeling methods.

In summary, automatic round bottle labelers transform packaging lines by delivering speed, accuracy, adaptability, quality, and cost-effectiveness, making them an indispensable component of modern packaging operations.