Inhoudsopgave

Benefits of Using a Chili Sauce Bottling Machine for Filling, Sealing, and Capping

Chili sauce is a popular condiment that adds a spicy kick to a variety of dishes. Whether it’s used as a dipping sauce, marinade, or ingredient in a recipe, chili sauce is a versatile and flavorful addition to any meal. For businesses that produce and sell chili sauce, having an efficient and reliable bottling machine is essential for filling, sealing, and capping bottles quickly and accurately.

One of the main benefits of using a chili sauce bottling machine is the speed and efficiency it offers. Manual bottling processes can be time-consuming and labor-intensive, requiring workers to fill each bottle by hand, seal it, and cap it. This can lead to inconsistencies in the amount of sauce in each bottle, as well as a slower production rate. With a bottling machine, the process is automated, allowing for faster filling, sealing, and capping of bottles. This not only increases production efficiency but also ensures a consistent product every time.

In addition to speed and efficiency, a chili sauce bottling machine also offers precision and accuracy in filling bottles. These machines are equipped with sensors and controls that can accurately measure and dispense the desired amount of sauce into each bottle. This helps to minimize waste and ensure that each bottle is filled to the correct level, providing a consistent product for consumers. With manual filling processes, it can be difficult to achieve the same level of precision and accuracy, leading to variations in product quality.

Another benefit of using a chili sauce bottling machine is the improved hygiene and cleanliness it provides. Manual bottling processes can be messy, with the potential for spills and contamination. Bottling machines are designed to be sanitary and easy to clean, with stainless steel construction and smooth surfaces that can be easily wiped down and sanitized. This helps to maintain the quality and safety of the product, reducing the risk of contamination and ensuring that each bottle of chili sauce is safe for consumption.

Furthermore, using a bottling machine for filling, sealing, and capping chili sauce bottles can also help to reduce labor costs and increase productivity. By automating the bottling process, businesses can streamline their production line and free up workers to focus on other tasks. This can lead to cost savings and increased efficiency, allowing businesses to produce more chili sauce in less time and with fewer resources.

Overall, the benefits of using a chili sauce bottling machine for filling, sealing, and capping bottles are numerous. From increased speed and efficiency to improved precision and accuracy, these machines offer a range of advantages for businesses that produce and sell chili sauce. By investing in a bottling machine, businesses can improve their production processes, maintain product quality, and increase productivity, ultimately leading to a more successful and profitable operation.

Step-by-Step Guide on How to Operate a Chili Sauce Bottling Machine for Efficient Production

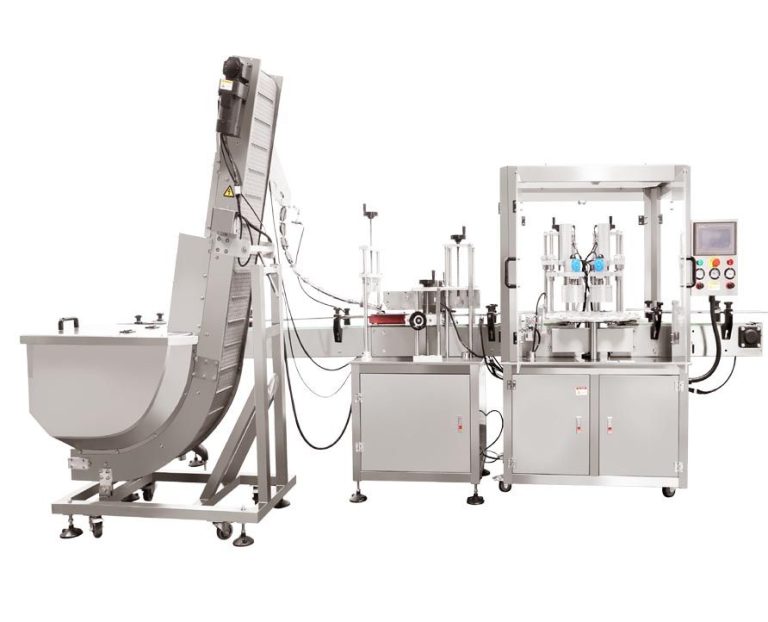

Chili sauce is a popular condiment that adds a spicy kick to a variety of dishes. For businesses looking to mass-produce chili sauce, investing in a chili sauce bottling machine is essential for efficient production. These machines are designed to fill, seal, and cap bottles of chili sauce quickly and accurately, saving time and labor costs. In this article, we will provide a step-by-step guide on how to operate a chili sauce bottling machine for efficient production.

First and foremost, it is important to ensure that the chili sauce bottling machine is set up correctly before use. This includes properly connecting the machine to a power source, as well as ensuring that all components are clean and in good working condition. Once the machine is set up, the next step is to prepare the chili sauce for bottling. This involves heating the sauce to the appropriate temperature and ensuring that it is free of any contaminants.

Once the chili sauce is prepared, it can be poured into the hopper of the bottling machine. The machine will then automatically fill each bottle with the desired amount of chili sauce. It is important to monitor the machine during this process to ensure that the bottles are being filled accurately and that there are no leaks or spills.

After the bottles are filled, the next step is to seal them. This is typically done using a capping machine, which will securely seal each bottle with a cap or lid. Again, it is important to monitor the machine during this process to ensure that the caps are being applied correctly and that there are no issues with the sealing process.

Once the bottles are filled and sealed, they can be labeled and packaged for distribution. This can be done manually or using a labeling and packaging machine, depending on the scale of production. It is important to ensure that the labels are applied accurately and that the bottles are packaged securely to prevent breakage during shipping.

In conclusion, operating a chili sauce bottling machine requires careful attention to detail and proper maintenance. By following the steps outlined in this guide, businesses can ensure efficient production of chili sauce and maintain high quality standards. Investing in a chili sauce bottling machine can help businesses streamline their production process and increase output, ultimately leading to greater profitability.

-768x576.png)