In the food industry, sauce production is a dynamic and competitive field. The introduction of the automatic sauce piston filling machine has brought about a significant transformation, revolutionizing the way sauces are produced, packaged, and delivered to consumers.

Inhoudsopgave

Enhanced Precision in Filling

One of the most notable impacts of the automatic sauce piston filling machine is the remarkable precision it offers. Traditional filling methods often struggled to dispense the exact amount of sauce into each container. This could lead to inconsistent product quality, with some containers having too much sauce and others too little.

The piston mechanism in these machines, however, is designed to measure and dispense a precise volume of sauce every time. For example, in a factory producing premium hot sauce, each bottle needs to have the same amount of sauce to maintain the brand’s reputation for quality. The automatic sauce piston filling machine ensures that whether it’s a small – batch artisanal sauce or a large – scale commercial production, every bottle gets the exact quantity of sauce, meeting both customer expectations and regulatory requirements.

Increased Production Speed

Time is a critical factor in the food production business. Manual filling processes are time – consuming and labor – intensive, limiting the amount of sauce that can be produced in a given period. The automatic sauce piston filling machine changes this equation entirely.

These machines can operate at high speeds, filling a large number of containers in a short span. In a busy sauce production facility, an automatic filling machine can fill hundreds or even thousands of bottles per hour. This high – speed production allows companies to meet market demand more efficiently, whether it’s for a popular condiment during the holiday season or a new sauce launch. It also enables businesses to scale up their production quickly in response to growing consumer interest.

Handling Different Sauce Viscosities

Sauces come in a wide range of viscosities, from thin and watery to thick and chunky. The automatic sauce piston filling machine is highly versatile and can handle all types of sauces with ease.

For thin sauces like soy sauce or salad dressing, the machine can adjust its filling speed and pressure to ensure a smooth and continuous flow. When it comes to thick and chunky sauces such as salsa or meat – based barbecue sauce, the piston mechanism can effectively push the sauce through the filling nozzle without getting clogged. This adaptability means that a single machine can be used to fill different types of sauces, eliminating the need for multiple filling systems and reducing equipment costs.

Improved Hygiene and Sanitation

Hygiene is of utmost importance in the food industry. Manual filling processes are more prone to contamination due to human contact and the potential for spills and drips. The automatic sauce piston filling machine addresses these concerns with its hygienic design.

These machines are typically made of food – grade materials that are easy to clean and sanitize. The smooth surfaces and sealed components prevent the accumulation of sauce residues, which can harbor bacteria. Additionally, many automatic filling machines are designed with features such as quick – disconnect parts, making it easy to disassemble and clean the machine thoroughly between production runs. This ensures that the sauce remains safe for consumption and meets strict food safety standards.

Reduced Labor Costs

In a traditional sauce production setup, a significant amount of labor is required for the filling process. Workers need to carefully measure and pour the sauce into each container, which is not only time – consuming but also physically demanding.

The automatic sauce piston filling machine reduces the need for manual labor. With its automated operation, a single operator can oversee the filling process of multiple machines. This not only cuts down on labor costs but also reduces the risk of human error. Workers can be redeployed to other tasks such as quality control or packaging, further optimizing the production process.

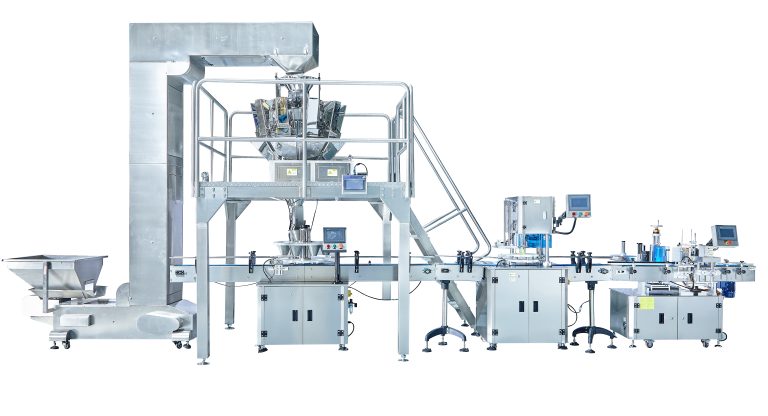

Integration with the Production Line

The automatic sauce piston filling machine can be seamlessly integrated into existing sauce production lines. It can work in conjunction with other equipment such as conveyors, cappers, and labelers.

Once the sauce is filled into the containers, the conveyor system can transport them to the capping machine for sealing and then to the labeling machine for branding. This integration creates a continuous and efficient production flow, minimizing downtime between different stages of the production process. It also allows for better coordination and synchronization, resulting in a more streamlined and productive sauce production operation.

In conclusion, the automatic sauce piston filling machine has transformed sauce production in numerous ways. Its precision, speed, versatility, hygiene, labor – saving capabilities, and integration potential have made it an indispensable tool for modern sauce manufacturers, enabling them to produce high – quality sauces more efficiently and cost – effectively.