Inhoudsopgave

Proper Maintenance Tips for Automatic Can Seaming Machines

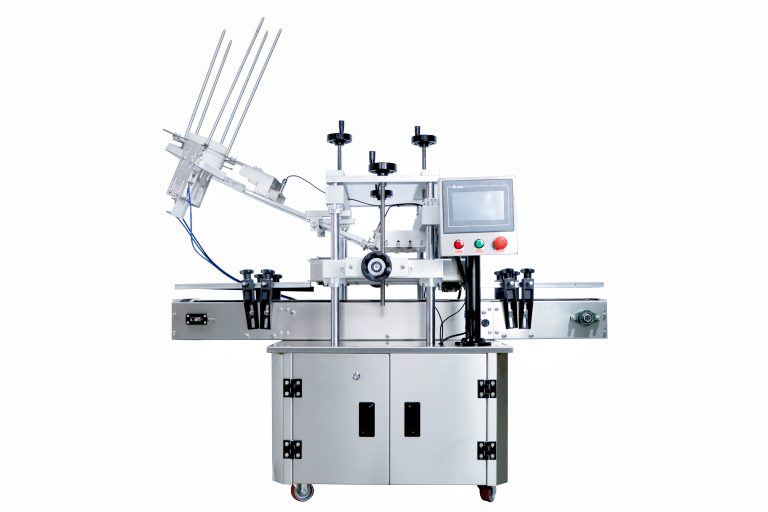

Automatic can seaming machines are essential equipment in the food and beverage industry, as they ensure that cans are properly sealed to maintain product freshness and prevent contamination. To ensure the smooth operation of these machines and prolong their lifespan, proper maintenance is crucial. In this article, we will discuss some tips on how to maintain and operate an automatic can seaming machine effectively.

First and foremost, it is important to regularly clean the machine to prevent the buildup of dirt, debris, and food particles. This can be done by wiping down the exterior of the machine with a damp cloth and using a brush to remove any residue from the seams and rollers. Additionally, it is recommended to use a mild detergent to clean the machine thoroughly and ensure that all parts are free from any contaminants.

In addition to cleaning, it is important to regularly inspect the machine for any signs of wear and tear. This includes checking the seams and rollers for any damage or corrosion, as well as ensuring that all moving parts are properly lubricated. Any worn or damaged parts should be replaced immediately to prevent further damage to the machine and ensure that it continues to operate efficiently.

Another important aspect of maintaining an automatic can seaming machine is to calibrate it regularly to ensure that it is operating at optimal performance. This can be done by adjusting the settings on the machine to ensure that the seams are properly sealed and that the cans are sealed tightly. It is also important to check the pressure settings on the machine to ensure that they are within the recommended range for the type of cans being sealed.

Furthermore, it is important to train operators on how to properly operate the machine to prevent any mishaps or accidents. This includes ensuring that operators are familiar with the machine’s controls and safety features, as well as providing proper training on how to troubleshoot common issues that may arise during operation. By providing proper training, operators can ensure that the machine is operated safely and efficiently, reducing the risk of downtime and costly repairs.

In conclusion, proper maintenance of an automatic can seaming machine is essential to ensure that it operates efficiently and effectively. By regularly cleaning the machine, inspecting it for wear and tear, calibrating it regularly, and training operators on how to operate it safely, you can prolong the lifespan of the machine and prevent costly repairs. By following these tips, you can ensure that your automatic can seaming machine continues to seal cans properly and maintain product freshness for years to come.

Troubleshooting Common Issues with Automatic Can Seaming Machines

Automatic can seaming machines are essential tools in the food and beverage industry for sealing cans securely and efficiently. However, like any piece of machinery, they can encounter issues that may disrupt production. In this article, we will discuss some common problems that can arise when operating an automatic can seaming machine and provide troubleshooting tips to help you resolve them.

One common issue that operators may encounter is inconsistent seam quality. This can result in leaks or improperly sealed cans, which can compromise the integrity of the product inside. To address this issue, first, check the seaming rollers to ensure they are properly aligned and in good condition. Misaligned or worn rollers can lead to uneven seams. Additionally, make sure that the seaming chuck is clean and free of any debris that could affect the sealing process.

Another common problem is can slippage during the seaming process. This can occur if the can is not properly centered or if the seaming chuck is not gripping the can securely. To prevent can slippage, make sure that the can is positioned correctly in the seaming chuck before starting the machine. Adjust the chuck if necessary to ensure a tight grip on the can throughout the seaming process.

In some cases, operators may encounter issues with the seaming head not closing properly. This can result in incomplete seams or damaged cans. To address this problem, check the air pressure and adjust it as needed to ensure that the seaming head closes with the correct amount of force. Additionally, inspect the seaming head for any obstructions or damage that could be preventing it from closing properly.

Another common issue that operators may face is excessive noise or vibration during operation. This can be caused by a variety of factors, including misaligned components, worn parts, or loose fasteners. To address this issue, carefully inspect the machine for any loose or damaged parts and tighten or replace them as needed. Additionally, make sure that all components are properly aligned to reduce noise and vibration during operation.

Finally, operators may encounter issues with the seam not holding up during storage or transportation. This can be a result of insufficient seam tightness or improper seam formation. To address this issue, adjust the seaming parameters to ensure a tight and consistent seam. Additionally, inspect the seam for any defects or irregularities that could compromise its integrity.

In conclusion, operating an automatic can seaming machine requires attention to detail and regular maintenance to ensure smooth and efficient operation. By addressing common issues such as inconsistent seam quality, can slippage, seaming head closure problems, excessive noise or vibration, and seam integrity, operators can maintain the performance of their machines and produce high-quality sealed cans. Remember to follow manufacturer guidelines for maintenance and troubleshooting to keep your automatic can seaming machine running smoothly.