The Canned Prepared Soup Filling and Packaging Production Line is a remarkable feat of engineering that plays a crucial role in the food industry. Let’s delve into its key aspects and advantages.

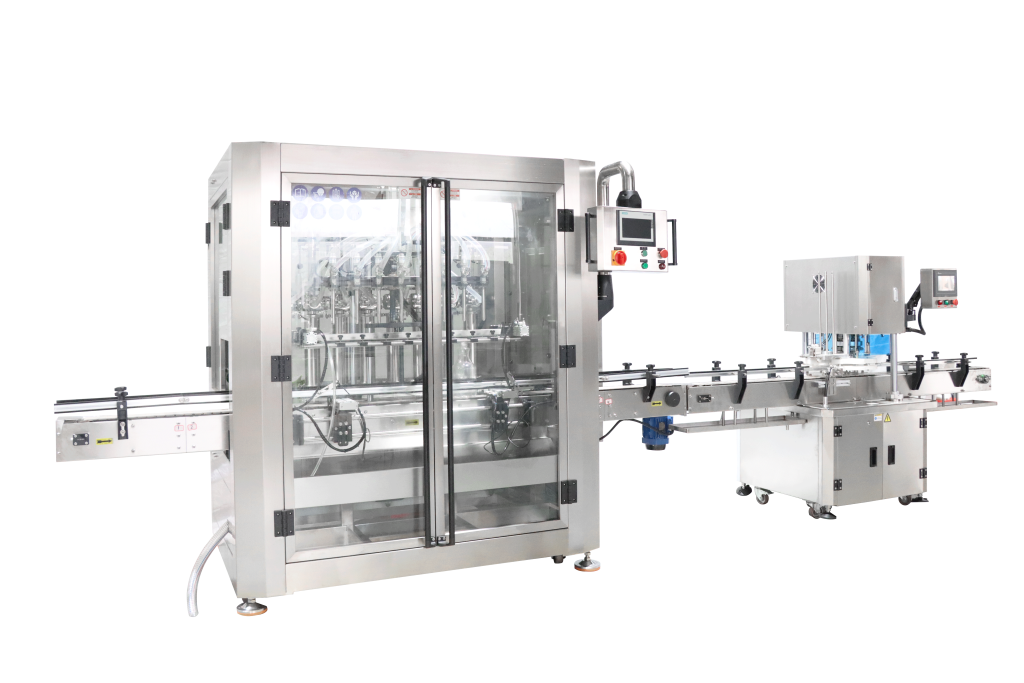

This production line ensures a seamless and rapid filling process for canned soup. The precision and speed of the filling mechanism guarantee that each can is filled accurately, minimizing waste and maximizing productivity.

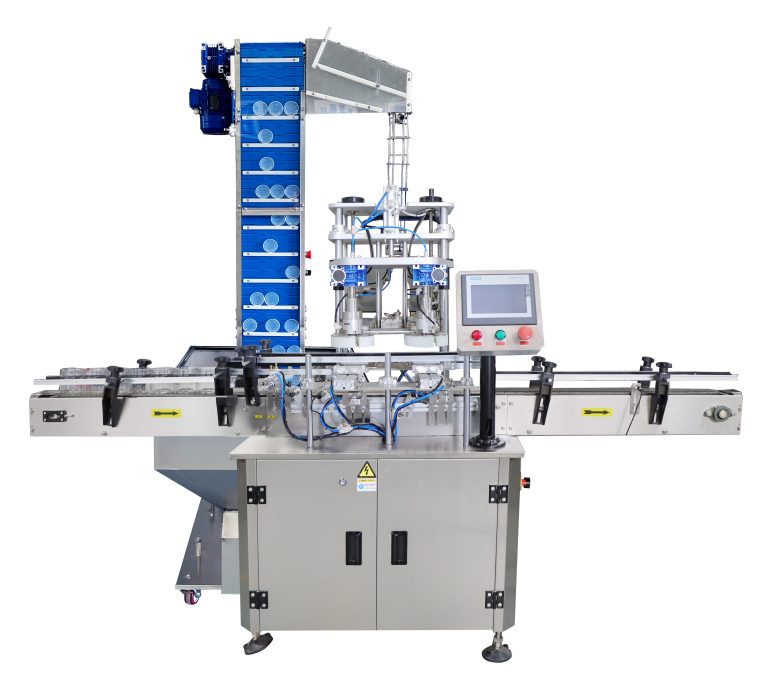

The packaging aspect of the line is equally impressive. It incorporates advanced technologies to create attractive and secure packaging that protects the soup from external factors and enhances its shelf appeal.

The line is highly customizable, allowing manufacturers to adapt it to different soup varieties, can sizes, and packaging designs. This flexibility enables businesses to meet diverse market demands and stay competitive.

Automation is a key feature that reduces the reliance on manual labor, lowers the risk of human error, and ensures consistent quality across all batches of canned soup.

The integration of quality control checks throughout the production process ensures that only the best products reach the market, maintaining consumer trust and brand reputation.

In conclusion, the Canned Prepared Soup Filling and Packaging Production Line is a vital asset for soup producers, offering efficiency, quality, and customization.