In the modern manufacturing landscape, Automatic Tape Around Seaming Machines play a crucial role in significantly boosting productivity.

These machines operate at speeds that far exceed manual methods. They can complete seaming tasks in a fraction of the time, allowing for a higher volume of production within a given period. This rapid output helps businesses meet tight deadlines and fulfill large orders promptly.

The consistency and accuracy offered by Automatic Tape Around Seaming Machines are key factors in productivity enhancement. Every seam is precisely taped, eliminating variations and reducing the need for rework or quality checks. This streamlined process saves valuable time and resources.

They also minimize human errors that often occur during manual taping. With automated operations, the chances of incorrect tape application or inconsistent pressure are greatly reduced, ensuring a smooth and efficient production flow.

The machines’ ability to handle continuous operation without significant fatigue or breaks ensures a consistent workflow. This eliminates downtime and keeps the production line moving steadily, maximizing productivity throughout the working hours.

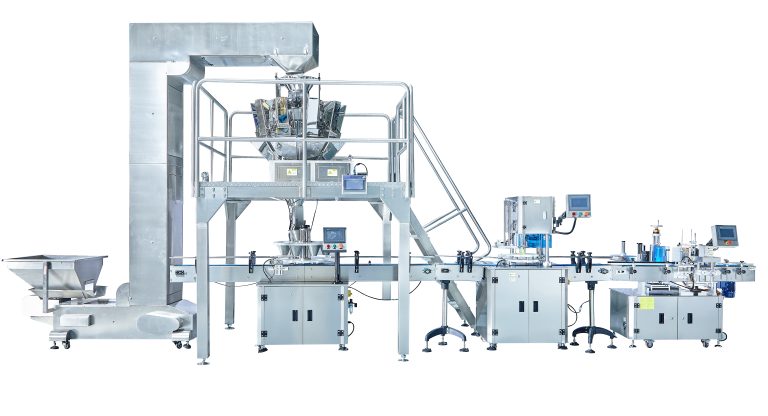

Furthermore, Automatic Tape Around Seaming Machines can be integrated with other manufacturing equipment and systems, creating a seamless production process. This integration optimizes the overall workflow and reduces bottlenecks, contributing to enhanced productivity.

In conclusion, the role of Automatic Tape Around Seaming Machines in enhancing productivity is undeniable. They provide a reliable and efficient solution that helps businesses stay competitive and meet the ever-growing demands of the market.