Table of Contents

Benefits of Using a Can Flip Machine in Your Manufacturing Process

In the world of manufacturing, efficiency is key. Every step in the production process must be optimized to ensure that products are made quickly and accurately. One way to improve efficiency in the manufacturing process is by using a can flip machine. These machines are designed to flip cans or containers upside down, allowing for easier labeling, filling, or inspection. In this article, we will explore the benefits of using a can flip machine in your manufacturing process.

One of the main benefits of using a can flip machine is increased productivity. By automating the process of flipping cans, workers can focus on other tasks that require more skill and attention to detail. This can help to speed up the production process and reduce the time it takes to manufacture a product. Additionally, can flip machines are typically faster and more accurate than manual flipping, leading to a higher output and fewer errors.

Another benefit of using a can flip machine is improved safety. Flipping cans manually can be a tedious and potentially dangerous task, especially if the cans are heavy or awkwardly shaped. By using a can flip machine, workers can avoid the risk of injury and focus on more important aspects of the manufacturing process. This can help to create a safer work environment and reduce the likelihood of accidents occurring on the production line.

In addition to increased productivity and improved safety, can flip machines also offer a higher level of consistency and quality control. These machines are designed to flip cans in a precise and uniform manner, ensuring that each can is flipped the same way every time. This can help to reduce variations in the production process and create a more consistent end product. Additionally, can flip machines can be programmed to flip cans at specific angles or speeds, allowing for greater control over the manufacturing process.

Furthermore, using a can flip machine can help to reduce waste and improve efficiency in the manufacturing process. By flipping cans upside down, any excess liquid or residue can be drained out before the can is filled or sealed. This can help to prevent spills or leaks during the filling process and ensure that each can is properly prepared for the next step in production. Additionally, can flip machines can be integrated into existing production lines, allowing for a seamless transition between flipping and other manufacturing processes.

Overall, the benefits of using a can flip machine in your manufacturing process are clear. These machines can help to increase productivity, improve safety, ensure consistency, reduce waste, and enhance efficiency. By incorporating a can flip machine into your production line, you can streamline the manufacturing process and create a more efficient and effective operation. Whether you are a small business or a large corporation, investing in a can flip machine can help to take your manufacturing process to the next level.

How to Choose the Right Can Flip Machine for Your Business

Can flip machines are essential equipment for businesses that deal with canned products. These machines are designed to efficiently flip cans upside down, allowing for proper labeling, inspection, and other processes. Choosing the right can flip machine for your business is crucial to ensure smooth operations and high-quality output. In this article, we will discuss the factors to consider when selecting a can flip machine that best suits your business needs.

One of the first things to consider when choosing a can flip machine is the size and capacity of the machine. The size of the machine should be able to accommodate the volume of cans that your business processes on a daily basis. It is important to choose a machine that can handle the workload without causing delays or bottlenecks in production. Additionally, consider the space available in your facility to ensure that the machine fits comfortably and does not disrupt other operations.

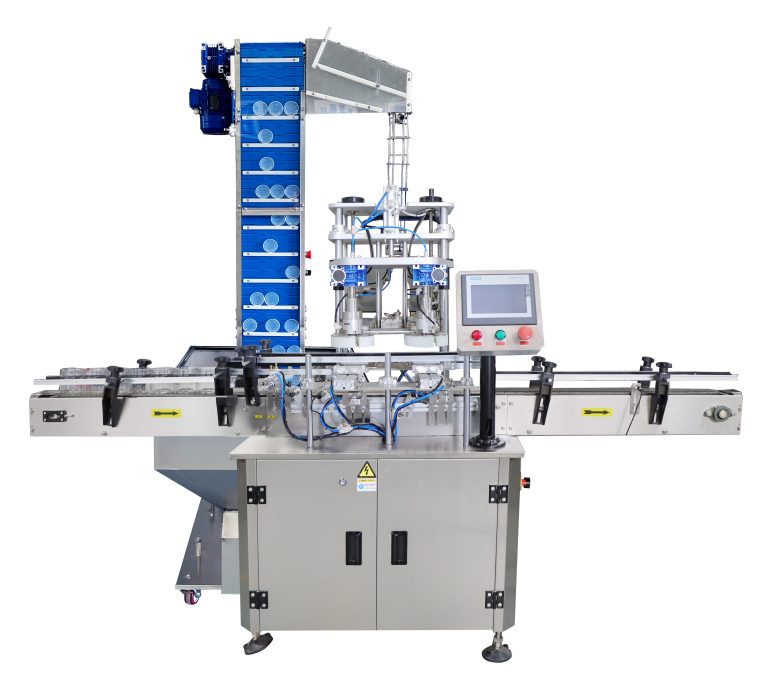

Another important factor to consider is the speed and efficiency of the can flip machine. The machine should be able to flip cans quickly and accurately to maintain a smooth production flow. Look for machines that offer adjustable speed settings to accommodate different types of cans and production requirements. A fast and efficient can flip machine can help increase productivity and reduce downtime, ultimately improving the overall efficiency of your business.

When choosing a can flip machine, it is also important to consider the durability and reliability of the machine. Look for machines made from high-quality materials that can withstand the rigors of daily use in a production environment. Additionally, choose a machine from a reputable manufacturer with a track record of producing reliable equipment. Investing in a durable and reliable can flip machine will help minimize maintenance costs and downtime, ensuring that your business runs smoothly and efficiently.

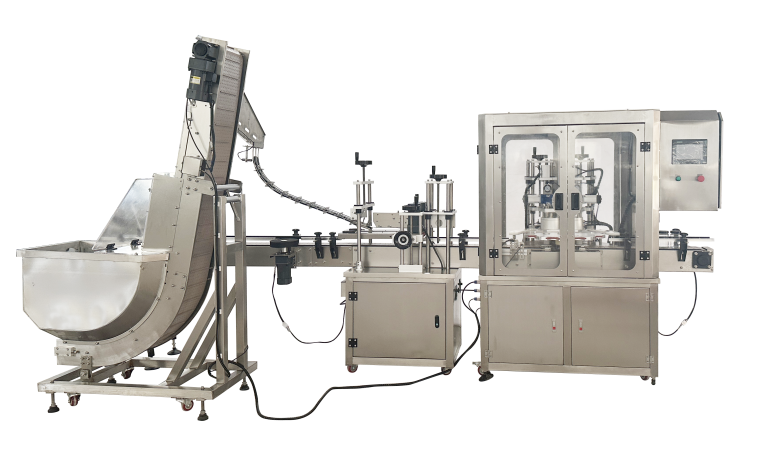

In addition to size, speed, and durability, consider the features and capabilities of the can flip machine. Look for machines that offer adjustable settings for flipping different sizes and types of cans. Some machines may also offer additional features such as automatic feeding, labeling, and inspection capabilities. Choose a machine that offers the features that are most important for your business operations to maximize efficiency and productivity.

Finally, consider the cost of the can flip machine and your budget constraints. While it is important to invest in a high-quality machine that meets your business needs, it is also important to consider the cost and ensure that it fits within your budget. Compare prices from different manufacturers and suppliers to find a machine that offers the best value for your money. Keep in mind that investing in a quality can flip machine is a long-term investment that can help improve the efficiency and profitability of your business.

In conclusion, choosing the right can flip machine for your business is essential to ensure smooth operations and high-quality output. Consider factors such as size, speed, durability, features, and cost when selecting a machine that best suits your business needs. By investing in a high-quality can flip machine, you can improve productivity, reduce downtime, and ultimately increase the efficiency and profitability of your business.