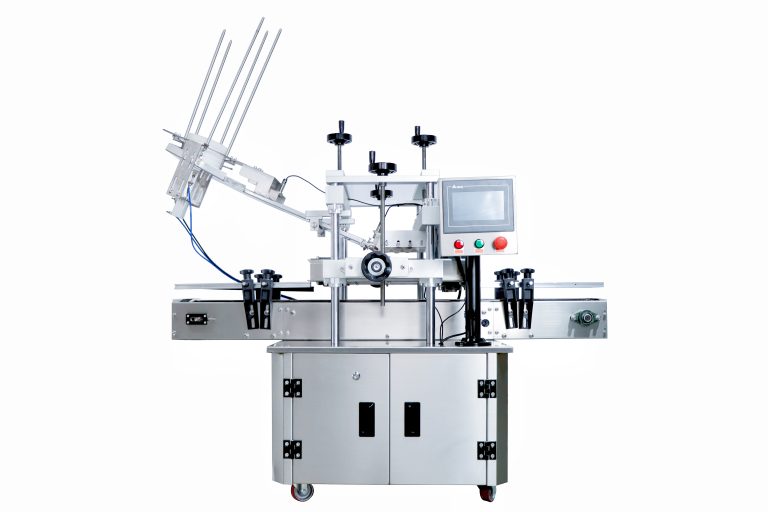

In the fast – evolving world of packaging technology, the automatic 8 wheels screw capping machine has emerged as a game – changer. Packed with a plethora of innovative features, it offers unparalleled efficiency, precision, and adaptability in the capping process.

Table of Contents

1. Advanced Torque Control System

One of the most remarkable features of this machine is its state – of – the – art torque control system. Unlike traditional capping machines, which may struggle to apply consistent torque, the 8 wheels screw capping machine uses advanced sensors and algorithms to ensure that each cap is tightened to the exact specified torque.

This is crucial for maintaining product integrity. For example, in the pharmaceutical industry, a precise torque is necessary to prevent contamination and ensure the efficacy of the medicine. The machine can be easily programmed to adjust the torque according to different cap types and container materials, providing a high level of flexibility.

2. High – Speed and Synchronized Operation

The eight – wheel design of the machine is a key innovation that enables high – speed capping. All eight wheels work in perfect synchronization, allowing for a rapid and continuous capping process. This significantly increases the production throughput compared to single – or few – wheel capping machines.

Moreover, the synchronized operation ensures that each cap is applied smoothly and evenly. There is no lag or misalignment between the wheels, which reduces the chances of cap damage or improper sealing. This high – speed and synchronized performance make it ideal for large – scale manufacturing operations.

3. Intelligent Cap Feeding Mechanism

The automatic 8 wheels screw capping machine is equipped with an intelligent cap feeding mechanism. This mechanism can handle a variety of cap sizes and shapes, from small plastic caps to large metal caps. It uses sensors and conveyors to sort and feed the caps to the capping wheels in an orderly manner.

The intelligent design also allows for quick changeovers between different cap types. Operators can simply adjust a few settings, and the machine will automatically adapt to the new caps. This reduces downtime during production and increases overall efficiency.

4. User – Friendly Interface

Another innovative feature is the user – friendly interface. The machine is designed with a touch – screen control panel that is easy to navigate. Operators can access all the machine’s functions and settings through the interface, including torque adjustment, speed control, and cap feeding parameters.

The interface also provides real – time feedback on the machine’s performance, such as the number of caps applied, the torque values, and any error messages. This allows operators to monitor the capping process closely and make adjustments as needed, without the need for extensive technical knowledge.

5. Self – Diagnostic and Maintenance Features

The automatic 8 wheels screw capping machine comes with self – diagnostic capabilities. It can detect potential issues, such as mechanical failures, sensor malfunctions, or cap jams, and alert the operators immediately. This early detection helps to prevent costly breakdowns and reduces production downtime.

In addition, the machine has built – in maintenance features. It can provide reminders for routine maintenance tasks, such as lubrication and part replacement. Some models even have the ability to perform self – cleaning operations, which helps to keep the machine in optimal condition and extends its lifespan.

6. Compatibility with Different Container Types

This capping machine is highly compatible with various container types, including bottles, jars, and cans. It can handle containers made of different materials, such as glass, plastic, and metal. The machine can be adjusted to accommodate different container heights and diameters, making it a versatile choice for manufacturers with diverse packaging needs.

In conclusion, the automatic 8 wheels screw capping machine’s innovative features make it a powerful and reliable tool in the packaging industry. Its advanced technology, high – speed operation, user – friendly design, and adaptability set it apart from traditional capping machines, helping manufacturers to achieve higher levels of productivity and quality in their packaging processes.

-768x576.png)