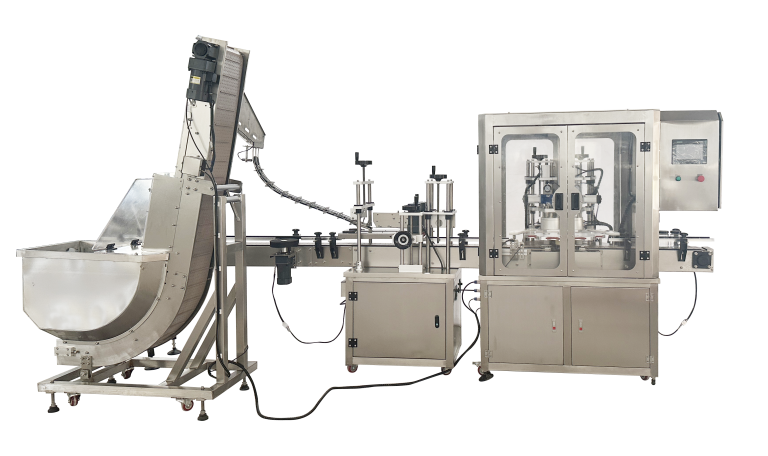

The Automatic Dual Head Servo Bottle Capping Machine stands out in the world of packaging equipment due to its array of innovative features.

One of the most notable innovations is its dual-head servo system. This design enables the machine to cap bottles at an astonishing speed, far surpassing traditional single-head machines. The synchronized operation of the two heads ensures maximum efficiency and productivity.

The precision control offered by the servo technology is another remarkable feature. It allows for exact and consistent capping, guaranteeing that each bottle is sealed perfectly. This level of accuracy not only enhances the quality of the packaged products but also reduces the chances of leakage or spoilage.

The machine’s adaptability is a key innovation. It can effortlessly handle various bottle shapes, sizes, and types of caps, providing manufacturers with the flexibility to meet diverse packaging requirements.

The intelligent monitoring and self-diagnosis system is yet another cutting-edge feature. It constantly keeps track of the machine’s performance, alerting operators of any potential issues and facilitating prompt maintenance. This helps minimize downtime and ensures continuous operation.

The user-friendly interface is also an important innovation. It simplifies the operation process, allowing even novice operators to quickly master the machine’s controls and settings.

In conclusion, the Automatic Dual Head Servo Bottle Capping Machine‘s innovative features make it a revolutionary addition to the packaging industry, offering enhanced efficiency, quality, and flexibility.