Table of Contents

Benefits of Using Seasoning Glass Jar Capping Machine

Seasoning glass jar capping machines are an essential piece of equipment for any food processing or packaging facility. These machines are designed to efficiently seal glass jars containing various seasoning products, ensuring a tight and secure closure that preserves the freshness and flavor of the contents. There are several benefits to using a seasoning glass jar capping machine, which we will explore in this article.

One of the primary advantages of using a seasoning glass jar capping machine is the speed and efficiency it offers. These machines are capable of capping hundreds of jars per hour, significantly increasing the productivity of your packaging line. This means that you can meet high production demands without sacrificing quality or consistency in the sealing process.

In addition to speed, seasoning glass jar capping machines also offer a high level of precision and accuracy. The automated capping process ensures that each jar is sealed with the correct amount of pressure, resulting in a consistent and reliable seal every time. This helps to minimize the risk of leaks or contamination, ensuring that your products reach consumers in perfect condition.

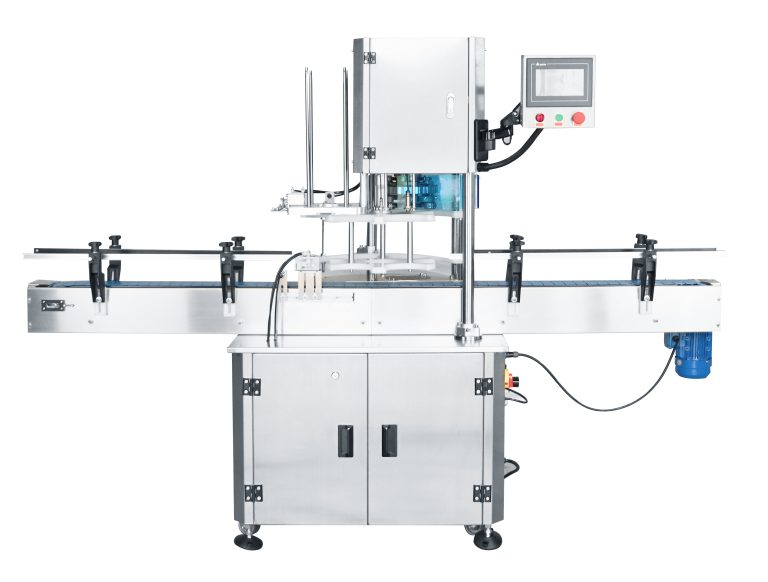

Another benefit of using a seasoning glass jar capping machine is the versatility it provides. These machines are designed to accommodate a wide range of jar sizes and shapes, making them suitable for packaging various types of seasoning products. Whether you are packaging small spice jars or larger containers of rubs and marinades, a glass jar capping machine can be easily adjusted to meet your specific packaging needs.

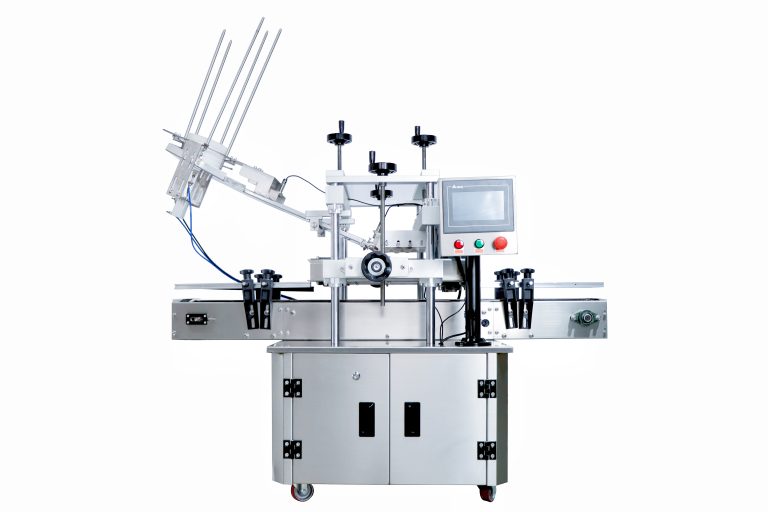

Furthermore, seasoning glass jar capping machines are easy to operate and maintain. Most machines are equipped with user-friendly controls and settings, allowing operators to quickly set up and adjust the capping process as needed. Additionally, these machines are built to withstand the rigors of continuous use, requiring minimal maintenance to keep them running smoothly.

Using a seasoning glass jar capping machine can also help to improve the overall quality and appearance of your products. The tight and secure seal provided by these machines helps to preserve the freshness and flavor of the seasoning inside the jars, ensuring that customers receive a high-quality product every time. Additionally, the professional-looking seal created by a capping machine can enhance the shelf appeal of your products, making them more attractive to consumers.

In conclusion, seasoning glass jar capping machines offer a wide range of benefits for food processing and packaging facilities. From increased speed and efficiency to improved precision and versatility, these machines are an essential tool for ensuring the quality and consistency of your seasoning products. By investing in a glass jar capping machine, you can streamline your packaging process, enhance the appearance of your products, and ultimately increase customer satisfaction.

How to Choose the Right Seasoning Glass Jar Capping Machine for Your Business

Seasoning glass jar capping machines are essential equipment for businesses in the food industry that produce and package seasoning products. These machines are designed to efficiently cap glass jars filled with various types of seasonings, ensuring a tight seal to maintain product freshness and quality. Choosing the right seasoning glass jar capping machine for your business is crucial to ensure smooth operations and high-quality end products.

When selecting a seasoning glass jar capping machine, there are several factors to consider. One of the most important factors is the speed and efficiency of the machine. Depending on the size of your production line and the volume of jars you need to cap, you will need to choose a machine that can keep up with your production demands. Look for a machine that offers a high capping speed and can handle a large number of jars per hour to maximize efficiency.

Another important factor to consider is the type of capping mechanism used in the machine. There are several types of capping mechanisms available, including screw capping, press capping, and snap capping. Each type of capping mechanism has its own advantages and disadvantages, so it is important to choose a machine that uses a capping mechanism that is suitable for the type of jars and caps you will be using.

In addition to speed and capping mechanism, it is also important to consider the size and design of the machine. Make sure the machine is compact enough to fit into your production space and can be easily integrated into your existing production line. Look for a machine that is easy to operate and maintain, with user-friendly controls and a durable construction that can withstand the rigors of daily use.

Furthermore, consider the flexibility of the machine in terms of capping different sizes and types of jars. Some machines are designed to cap a specific size or type of jar, while others offer adjustable settings to accommodate a variety of jar sizes. Choose a machine that can easily be adjusted to cap different sizes of jars to ensure versatility in your production process.

When choosing a seasoning glass jar capping machine, it is also important to consider the level of automation and customization options available. Some machines offer fully automated capping processes, while others require manual intervention at certain stages. Consider your production needs and budget to determine the level of automation that is right for your business. Additionally, look for a machine that offers customization options to tailor the capping process to your specific requirements.

In conclusion, choosing the right seasoning glass jar capping machine for your business is essential to ensure efficient operations and high-quality end products. Consider factors such as speed, capping mechanism, size and design, flexibility, automation, and customization options when selecting a machine. By carefully evaluating these factors and choosing a machine that meets your specific needs, you can ensure smooth operations and consistent product quality in your seasoning production process.