Benefits of Using a Semi Auto Nitrogen Flush Can Seaming Machine

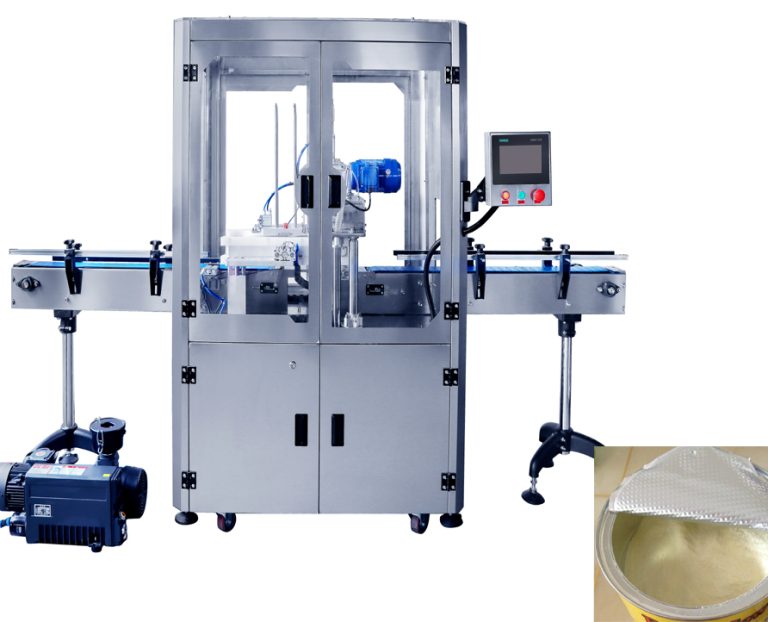

In the food and beverage industry, packaging plays a crucial role in maintaining the quality and freshness of products. One popular method used to extend the shelf life of canned products is nitrogen flushing. This process involves replacing the air inside the can with nitrogen gas before sealing it, creating a protective barrier that helps prevent oxidation and spoilage. To achieve this, many manufacturers rely on semi-automatic nitrogen flush can seaming machines.

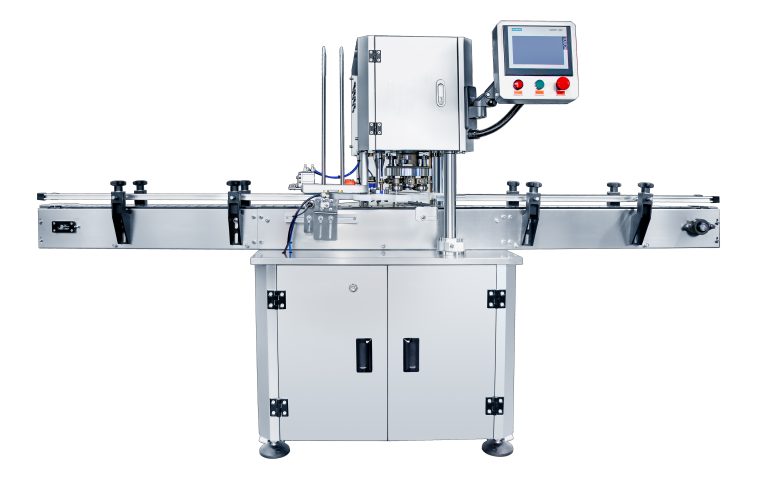

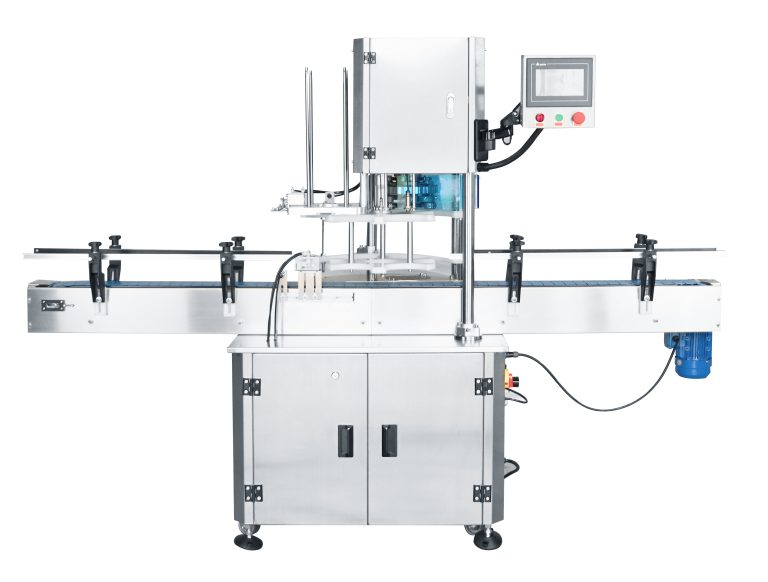

These machines are designed to streamline the canning process by automating the sealing and nitrogen flushing steps. By using a semi-auto nitrogen flush can seaming machine, manufacturers can increase efficiency, reduce labor costs, and improve the overall quality of their products.

One of the key benefits of using a semi-auto nitrogen flush can seaming machine is its ability to maintain product freshness. By replacing the air inside the can with nitrogen gas, manufacturers can create a controlled environment that helps preserve the flavor, texture, and nutritional value of the product. This is especially important for perishable items such as fruits, vegetables, and dairy products, which are prone to spoilage if not properly sealed.

In addition to extending shelf life, nitrogen flushing can also help improve the appearance of canned products. By removing oxygen from the can, manufacturers can prevent discoloration and maintain the vibrant colors of fruits and vegetables. This not only enhances the visual appeal of the product but also signals to consumers that the product is fresh and of high quality.

Another advantage of using a semi-auto nitrogen flush can seaming machine is its versatility. These machines are capable of sealing a wide range of can sizes and materials, making them suitable for a variety of products. Whether you are packaging soups, sauces, or beverages, a semi-auto nitrogen flush can seaming machine can accommodate your needs and ensure a secure seal every time.

Furthermore, semi-auto nitrogen flush can seaming machines are easy to operate and require minimal training. This makes them ideal for small to medium-sized businesses that may not have the resources to invest in fully automated packaging equipment. With a semi-auto nitrogen flush can seaming machine, manufacturers can increase production capacity without sacrificing quality or consistency.

In conclusion, the benefits of using a semi-auto nitrogen flush can seaming machine are clear. From extending shelf life and improving product appearance to increasing efficiency and reducing labor costs, these machines offer a range of advantages for manufacturers in the food and beverage industry. By investing in a semi-auto nitrogen flush can seaming machine, businesses can enhance the quality of their products, streamline their operations, and ultimately, satisfy their customers’ expectations for fresh, flavorful, and high-quality canned goods.