Table of Contents

Benefits of Using Single Head Auger Bottle Powder Filler

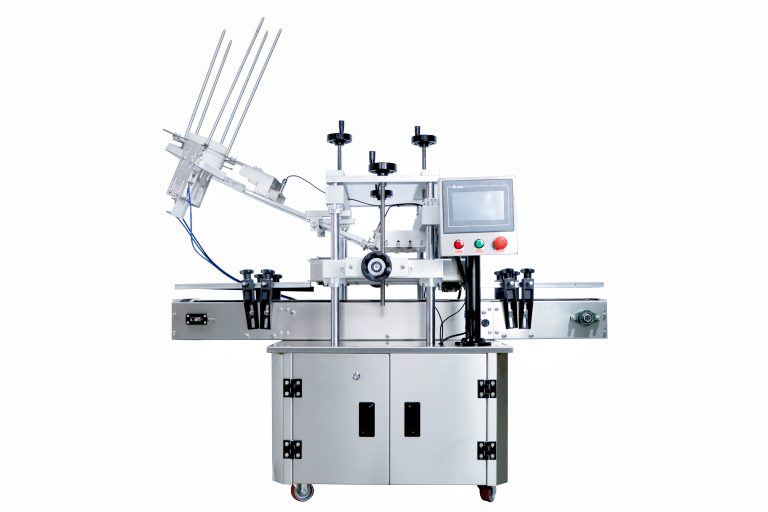

Single Head Auger Bottle Powder Filler is a versatile and efficient machine that is used in various industries for filling bottles with powdered substances. This machine is designed to accurately dispense a wide range of powders into bottles with precision and speed. There are several benefits to using a Single Head Auger Bottle Powder Filler, which make it a popular choice among manufacturers.

One of the key benefits of using a Single Head Auger Bottle Powder Filler is its ability to fill bottles quickly and accurately. This machine is equipped with a high-speed auger that can dispense powders at a consistent rate, ensuring that each bottle is filled to the desired level. This helps to increase productivity and reduce downtime, as the machine can fill a large number of bottles in a short amount of time.

In addition to its speed and accuracy, a Single Head Auger Bottle Powder Filler is also easy to use and maintain. The machine is designed with user-friendly controls that allow operators to adjust settings and monitor the filling process with ease. This makes it simple for operators to set up the machine for different types of powders and bottle sizes, ensuring that each fill is precise and consistent.

Furthermore, a Single Head Auger Bottle Powder Filler is a cost-effective solution for manufacturers looking to streamline their production process. By automating the filling process, companies can reduce labor costs and minimize the risk of human error. This can lead to significant savings over time, making the machine a smart investment for businesses looking to improve efficiency and profitability.

Another benefit of using a Single Head Auger Bottle Powder Filler is its versatility. This machine can be used to fill bottles of various shapes and sizes, making it suitable for a wide range of products. Whether you are filling bottles with spices, pharmaceuticals, or other powdered substances, a Single Head Auger Bottle Powder Filler can handle the job with ease.

Additionally, a Single Head Auger Bottle Powder Filler is a hygienic option for filling bottles with powders. The machine is designed with stainless steel components that are easy to clean and sanitize, ensuring that each fill is safe and contamination-free. This is especially important for industries such as food and pharmaceuticals, where cleanliness and product safety are top priorities.

Overall, a Single Head Auger Bottle Powder Filler offers numerous benefits for manufacturers looking to improve their filling process. From its speed and accuracy to its ease of use and versatility, this machine is a valuable asset for any production line. By investing in a Single Head Auger Bottle Powder Filler, companies can increase efficiency, reduce costs, and ensure that each bottle is filled to perfection.

How to Choose the Right Single Head Auger Bottle Powder Filler for Your Business

When it comes to packaging powdered products, having the right equipment is essential to ensure efficiency and accuracy. One popular option for filling bottles with powders is the single head auger bottle powder filler. This machine is designed to accurately dispense a predetermined amount of powder into each bottle, making it ideal for businesses that require precise measurements and consistent filling.

When choosing a single head auger bottle powder filler for your business, there are several factors to consider. The first thing to think about is the type of powder you will be filling the bottles with. Different powders have different properties, such as density and flow characteristics, which can affect the performance of the filler. It is important to choose a machine that is designed to handle the specific type of powder you will be working with.

Another important factor to consider is the speed and capacity of the filler. Depending on the size of your production line and the volume of bottles you need to fill, you may need a machine that can fill a certain number of bottles per minute. It is important to choose a filler that can keep up with the demands of your business without sacrificing accuracy.

In addition to speed and capacity, it is also important to consider the accuracy of the filler. The whole point of using a single head auger bottle powder filler is to ensure that each bottle is filled with the exact amount of powder required. Look for a machine that offers precise measurements and consistent filling to avoid waste and ensure product quality.

Ease of use and maintenance are also important factors to consider when choosing a single head auger bottle powder filler. Look for a machine that is easy to set up and operate, with user-friendly controls and clear instructions. Additionally, choose a filler that is easy to clean and maintain to keep it running smoothly and prevent downtime.

When shopping for a single head auger bottle powder filler, it is a good idea to do some research and compare different models and brands. Look for reviews and testimonials from other businesses that have used the machine to get an idea of its performance and reliability. Additionally, consider reaching out to manufacturers or suppliers for more information and to ask any questions you may have.

Overall, choosing the right single head auger bottle powder filler for your business is essential to ensure efficient and accurate filling of bottles with powdered products. Consider factors such as the type of powder you will be working with, speed and capacity, accuracy, ease of use and maintenance, and do your research to find the best machine for your needs. With the right filler, you can streamline your production process and ensure consistent quality in your products.

Common Issues and Troubleshooting Tips for Single Head Auger Bottle Powder Filler

Single head auger bottle powder fillers are commonly used in the pharmaceutical, food, and cosmetic industries to accurately fill bottles with powdered products. While these machines are efficient and reliable, like any piece of equipment, they can encounter issues that may affect their performance. In this article, we will discuss some common issues that may arise with single head auger bottle powder fillers and provide troubleshooting tips to help resolve them.

One common issue that operators may encounter with single head auger bottle powder fillers is inconsistent filling. This can be caused by a variety of factors, such as incorrect settings, worn or damaged parts, or product inconsistencies. To troubleshoot this issue, operators should first check the machine’s settings to ensure that they are correct for the specific product being filled. They should also inspect the auger and other components for any signs of wear or damage, as this can affect the machine’s ability to dispense powder accurately. Additionally, operators should ensure that the product being filled is consistent in texture and density, as variations in these factors can also lead to inconsistent filling.

Another common issue with single head auger bottle powder fillers is clogging. Clogging can occur when the powder being dispensed is too fine or when the machine’s auger is not properly aligned or functioning correctly. To troubleshoot this issue, operators should first check the consistency of the powder being used and make any necessary adjustments to prevent clogging. They should also inspect the auger for any obstructions or misalignments and correct them as needed. Regular maintenance and cleaning of the machine can also help prevent clogging issues from occurring.

In some cases, operators may encounter issues with the machine’s speed or efficiency. This can be caused by a variety of factors, such as incorrect settings, worn parts, or improper maintenance. To troubleshoot this issue, operators should first check the machine’s settings to ensure that they are optimized for the specific product being filled. They should also inspect the machine for any signs of wear or damage and replace any worn parts as needed. Regular maintenance, such as lubricating moving parts and cleaning the machine regularly, can also help improve the machine’s speed and efficiency.

One final common issue that operators may encounter with single head auger bottle powder fillers is product waste. Product waste can occur when the machine dispenses more powder than is needed, leading to excess product being discarded. To troubleshoot this issue, operators should first check the machine’s settings to ensure that they are calibrated correctly for the specific product being filled. They should also inspect the machine for any signs of wear or damage that may be causing overfilling and correct them as needed. Operators can also adjust the machine’s settings to dispense smaller amounts of powder to reduce product waste.

In conclusion, single head auger bottle powder fillers are efficient and reliable machines that are commonly used in various industries. However, like any piece of equipment, they can encounter issues that may affect their performance. By following the troubleshooting tips outlined in this article, operators can address common issues with single head auger bottle powder fillers and ensure that their machines continue to operate efficiently and accurately.