It seems we can’t find what you’re looking for. Perhaps searching can help.

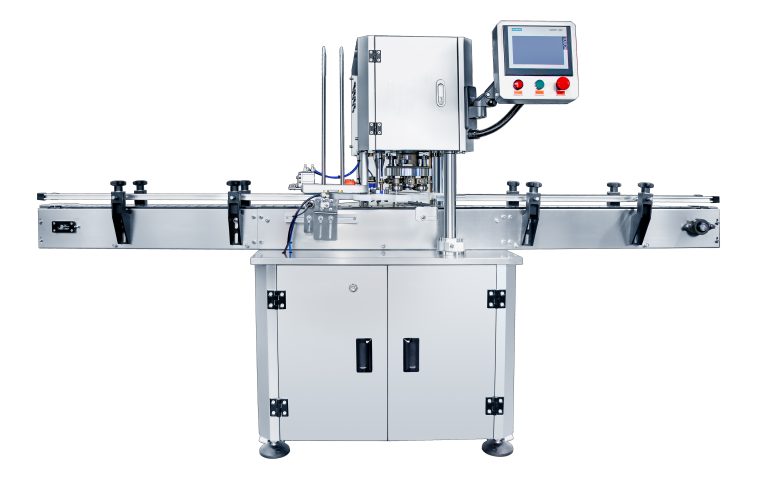

Automatic Tapioca Flour Filling Machine

Benefits of Using an Automatic Tapioca Flour Filling Machine Tapioca flour is a popular ingredient in many food products, from baked goods to bubble tea. However, filling containers with tapioca flour can be a time-consuming and messy process when done manually. This is where an automatic tapioca flour filling machine…