Table of Contents

Benefits of Using a Popcorn Plastic Jar Automatic Can Seamer Machine

Popcorn is a beloved snack enjoyed by people of all ages around the world. Whether you’re at the movies, watching a sports game, or simply relaxing at home, popcorn is a go-to treat that never fails to satisfy. With the rise in popularity of popcorn, especially flavored popcorn, there is a growing demand for efficient packaging solutions to ensure freshness and convenience for consumers. This is where the popcorn plastic jar automatic can seamer machine comes into play.

One of the key benefits of using a popcorn plastic jar automatic can seamer machine is its ability to streamline the packaging process. With traditional methods, sealing cans manually can be time-consuming and labor-intensive. However, with an automatic can seamer machine, the process is automated, saving time and reducing the need for manual labor. This not only increases efficiency but also allows for higher production volumes, meeting the demands of a growing market.

In addition to efficiency, using a popcorn plastic jar automatic can seamer machine also ensures consistency in packaging. Manual sealing can lead to variations in the quality of the seal, which can affect the freshness and shelf life of the product. With an automatic can seamer machine, each can is sealed with precision and accuracy, ensuring a tight and secure seal every time. This consistency not only enhances the overall quality of the product but also helps to maintain its freshness and flavor for longer periods.

Furthermore, the use of a popcorn plastic jar automatic can seamer machine can also help to reduce the risk of contamination. Manual sealing can expose the product to potential contaminants, such as dust, dirt, or bacteria, which can compromise the quality and safety of the product. By automating the sealing process, the risk of contamination is minimized, ensuring that the popcorn remains safe and hygienic for consumption.

Another benefit of using a popcorn plastic jar automatic can seamer machine is its versatility. These machines are designed to accommodate a wide range of can sizes and shapes, making them suitable for various packaging needs. Whether you’re packaging small individual servings or larger family-sized portions, an automatic can seamer machine can be adjusted to meet your specific requirements. This flexibility allows for greater customization and adaptability in packaging, catering to the diverse needs of consumers.

Moreover, the use of a popcorn plastic jar automatic can seamer machine can also help to reduce packaging waste. By ensuring a tight and secure seal, these machines help to prevent leaks and spills, reducing the likelihood of product wastage. Additionally, the use of plastic jars as packaging material is more environmentally friendly compared to traditional metal cans, as plastic is lighter and more easily recyclable. This not only benefits the environment but also helps to reduce costs associated with waste disposal.

In conclusion, the benefits of using a popcorn plastic jar automatic can seamer machine are numerous. From increased efficiency and consistency to reduced contamination and waste, these machines offer a range of advantages that can help to enhance the packaging process and improve the overall quality of the product. As the demand for popcorn continues to grow, investing in an automatic can seamer machine can be a valuable asset for businesses looking to stay competitive in the market.

How to Choose the Right Popcorn Plastic Jar Automatic Can Seamer Machine for Your Business

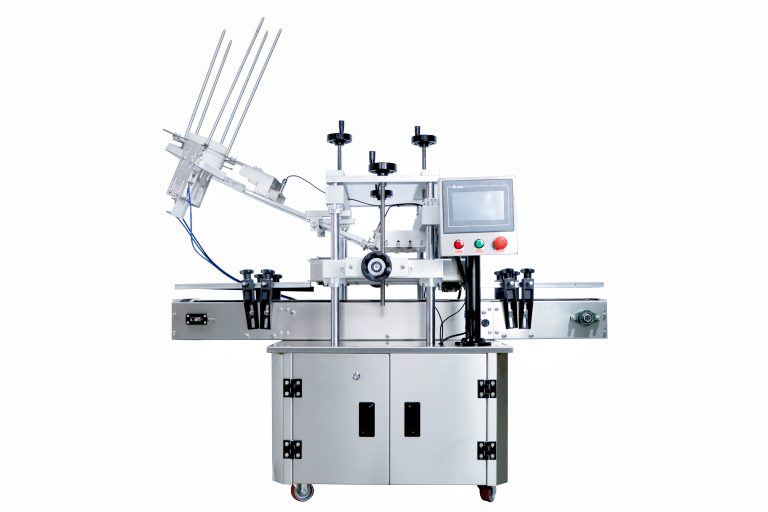

Popcorn is a beloved snack enjoyed by people of all ages. Whether you’re at the movies, watching a sports game, or simply craving a tasty treat, popcorn is a go-to option for many. For businesses looking to capitalize on the popularity of popcorn, investing in a popcorn plastic jar automatic can seamer machine can be a game-changer. These machines are designed to efficiently seal plastic jars filled with popcorn, ensuring freshness and quality for customers. However, with so many options available on the market, choosing the right machine for your business can be a daunting task.

When selecting a popcorn plastic jar automatic can seamer machine, there are several factors to consider. First and foremost, you’ll want to assess the size and capacity of the machine. Depending on the volume of popcorn you plan to produce, you’ll need to choose a machine that can handle the workload. Additionally, consider the speed at which the machine operates. A faster machine can increase productivity and efficiency, allowing you to meet customer demand more effectively.

Another important factor to consider is the durability and reliability of the machine. Investing in a high-quality machine that is built to last will save you time and money in the long run. Look for machines made from sturdy materials that can withstand the rigors of daily use. Additionally, consider the reputation of the manufacturer. Choose a machine from a reputable company with a track record of producing reliable products.

In addition to functionality and durability, it’s also important to consider the ease of use of the machine. A user-friendly machine will streamline your production process and reduce the likelihood of errors. Look for machines with intuitive controls and clear instructions to ensure smooth operation. Additionally, consider the maintenance requirements of the machine. Choose a machine that is easy to clean and maintain to prolong its lifespan and ensure optimal performance.

Cost is another important factor to consider when choosing a popcorn plastic jar automatic can seamer machine. While it’s important to stay within budget, it’s also crucial to consider the long-term value of the machine. Investing in a high-quality machine may require a larger upfront investment, but it can pay off in the form of increased productivity and efficiency. Consider the return on investment of the machine and weigh the cost against the benefits it will provide for your business.

Ultimately, choosing the right popcorn plastic jar automatic can seamer machine for your business requires careful consideration of several factors. By assessing the size, capacity, speed, durability, ease of use, maintenance requirements, and cost of the machine, you can make an informed decision that will benefit your business in the long run. With the right machine in place, you can streamline your production process, increase efficiency, and deliver high-quality popcorn to your customers.

Maintenance Tips for Keeping Your Popcorn Plastic Jar Automatic Can Seamer Machine in Top Condition

Popcorn plastic jar automatic can seamer machines are essential equipment for businesses in the food packaging industry. These machines are designed to efficiently seal cans of popcorn, ensuring that the product remains fresh and free from contaminants. To ensure that your popcorn plastic jar automatic can seamer machine continues to operate at its best, it is important to follow a regular maintenance schedule.

One of the most important maintenance tasks for your popcorn plastic jar automatic can seamer machine is cleaning. Regular cleaning helps to prevent the buildup of food particles and other debris that can clog the machine and affect its performance. To clean your machine, start by unplugging it and removing any remaining popcorn cans. Use a damp cloth to wipe down the exterior of the machine, paying special attention to the seams and crevices where food particles can accumulate. For the interior of the machine, use a brush or vacuum to remove any debris that may be trapped in the can seaming mechanism.

In addition to regular cleaning, it is also important to lubricate the moving parts of your popcorn plastic jar automatic can seamer machine. Lubrication helps to reduce friction between the machine’s components, which can prolong the life of the machine and improve its overall performance. Before lubricating your machine, be sure to consult the manufacturer’s guidelines for the type of lubricant to use and the recommended intervals for lubrication.

Another important maintenance task for your popcorn plastic jar automatic can seamer machine is inspecting the seals and gaskets. Seals and gaskets play a crucial role in ensuring that the cans are properly sealed, so it is important to check them regularly for signs of wear or damage. If you notice any cracks, tears, or other damage to the seals or gaskets, they should be replaced immediately to prevent leaks and contamination of the product.

In addition to cleaning, lubricating, and inspecting the seals and gaskets, it is also important to regularly check the alignment of the can seaming mechanism. Misalignment can cause the cans to be improperly sealed, leading to leaks and other issues. To check the alignment of your machine, run a test can through the seaming mechanism and inspect the seam for any irregularities. If you notice any issues with the alignment, consult the manufacturer’s guidelines for adjusting the machine to ensure proper alignment.

Regular maintenance is essential for keeping your popcorn plastic jar automatic can seamer machine in top condition. By following a regular maintenance schedule that includes cleaning, lubricating, inspecting seals and gaskets, and checking alignment, you can prolong the life of your machine and ensure that it continues to operate at its best. Remember to consult the manufacturer’s guidelines for specific maintenance tasks and intervals, and don’t hesitate to contact a professional if you encounter any issues that you are unable to resolve on your own. With proper maintenance, your popcorn plastic jar automatic can seamer machine will continue to seal cans of popcorn efficiently and effectively for years to come.