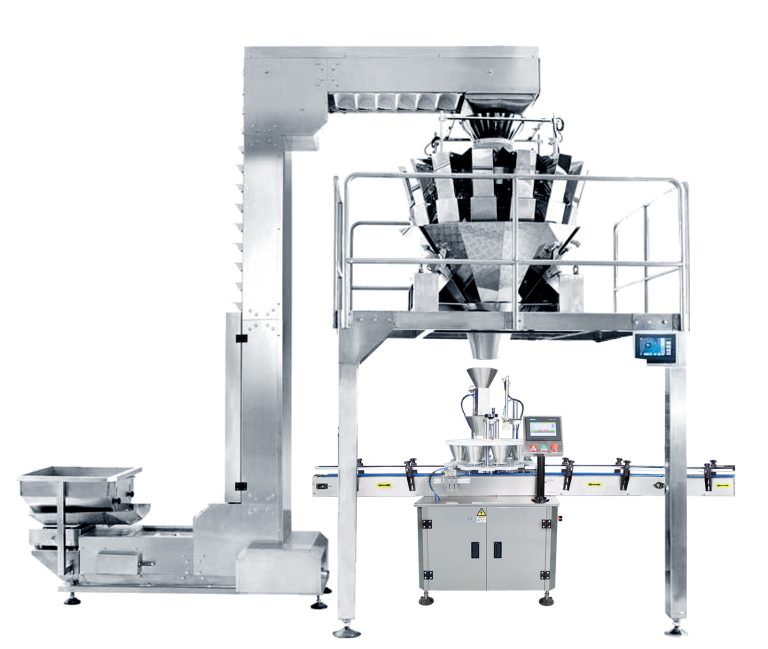

In the realm of granule packaging, automatic rotary fillers have risen to the forefront, establishing their dominance through an unwavering commitment to precision.

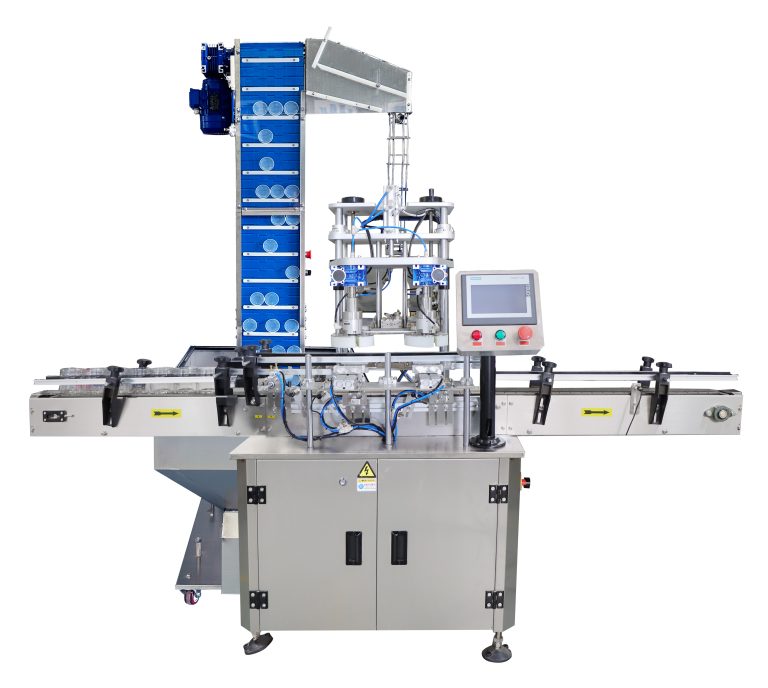

The key to their success lies in the seamless integration of advanced technology and mechanical design. Automatic rotary fillers operate with a smooth and continuous rotational movement that ensures a consistent and accurate filling process.

These fillers are engineered with highly calibrated measurement systems that can precisely dispense the exact amount of granules required for each package. This level of accuracy is crucial in maintaining product quality and meeting strict industry standards.

The speed and efficiency of automatic rotary fillers are also remarkable. They can handle a large volume of packages in a short period, without sacrificing the precision of the fill. This makes them ideal for high-production environments where time is of the essence.

-1024x683.jpg)

Furthermore, their ability to adapt to different granule sizes and shapes is a major advantage. Whether it’s fine powders or larger granules, the automatic rotary fillers can adjust and accommodate, ensuring a flawless packaging process every time.

The reliability and consistency of these fillers are another factor that sets them apart. With minimal downtime and low maintenance requirements, they offer a dependable solution for continuous production.

In addition, the integration of automated control systems allows for easy monitoring and adjustment of parameters, further enhancing the precision and performance of the filling process.

In conclusion, automatic rotary fillers dominate granule packaging due to their unparalleled precision, efficiency, adaptability, and reliability. They represent the cutting edge of packaging technology, delivering superior results and meeting the demanding needs of modern industries.