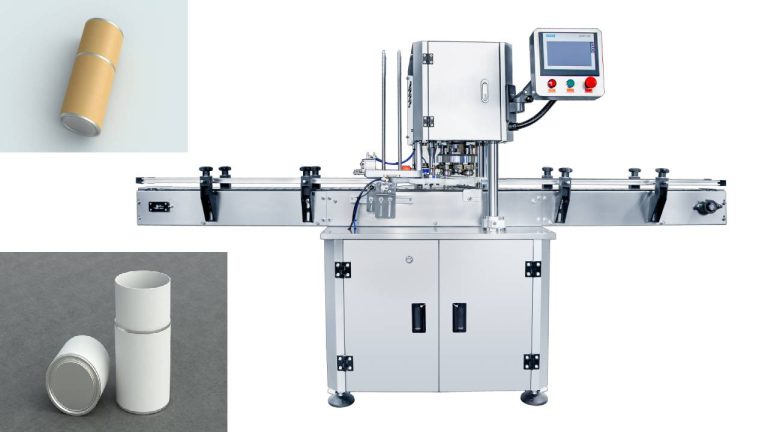

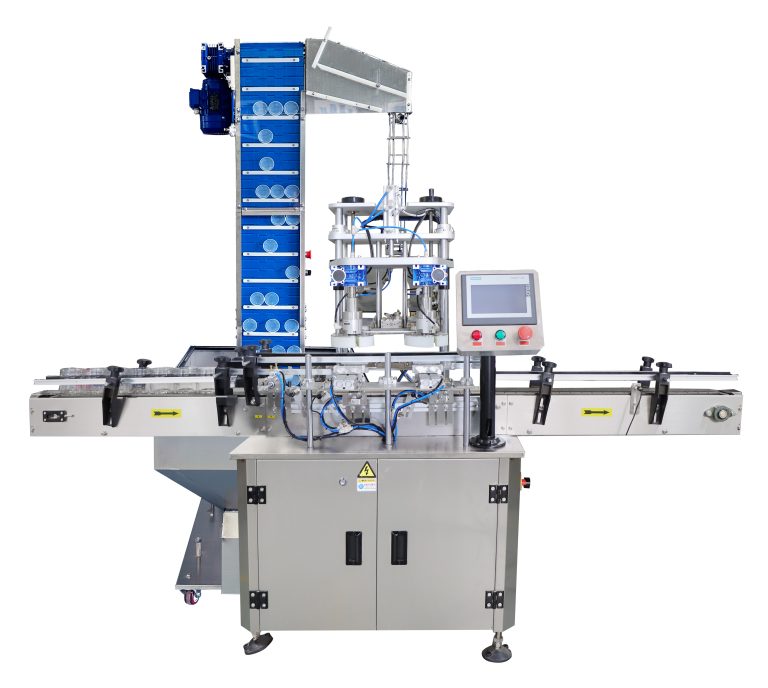

In the world of canned food production, the semi-automatic can closing machine plays a vital role. This specialized equipment is designed to seal cans with precision and efficiency, ensuring the longevity and safety of the contents.

One of the significant benefits of the semi-automatic can closing machine is its user-friendly operation. It strikes a balance between manual control and mechanical assistance, allowing operators to have a hands-on approach while still achieving consistent and reliable results.

This machine is engineered to handle a variety of can sizes and shapes, making it adaptable to different canned food products. Whether it’s fruits, vegetables, or meats, it can securely close the cans, maintaining the integrity of the packaging.

The quality of the closures is of paramount importance. The semi-automatic can closing machine ensures a tight seal, preventing air and contaminants from entering the cans. This helps to preserve the flavor, texture, and nutritional value of the canned food for an extended period.

It also offers a cost-effective solution for smaller-scale or medium-sized canned food producers. Without the need for a fully automated and expensive setup, businesses can still achieve efficient can closing without breaking the bank.

Maintenance of the machine is relatively straightforward. Regular cleaning and inspection of key components can ensure its longevity and continued optimal performance.

In conclusion, the semi-automatic can closing machine for canned food is an essential tool in the food processing industry. It helps producers meet quality standards, extend shelf life, and provide consumers with safe and delicious canned food products.

Keep an eye out for more insights into the world of food processing machinery!