Increased Efficiency Automated bottle cap capping machines have revolutionized the packaging industry by streamlining the process of sealing bottles with caps. These machines offer a wide range of advantages that can significantly improve efficiency in a production line. One of the key benefits of using automated capping machines is the…

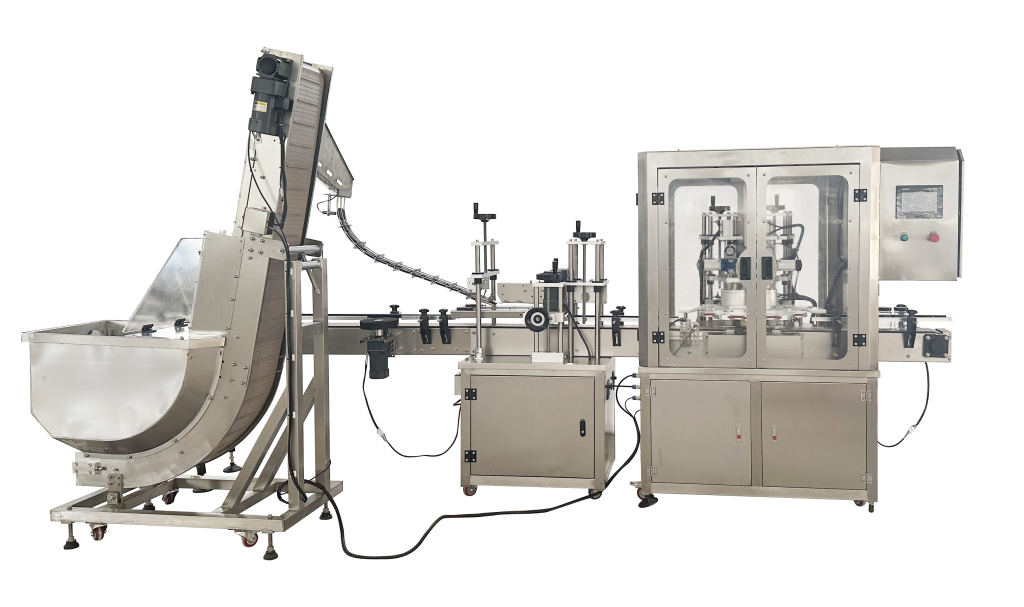

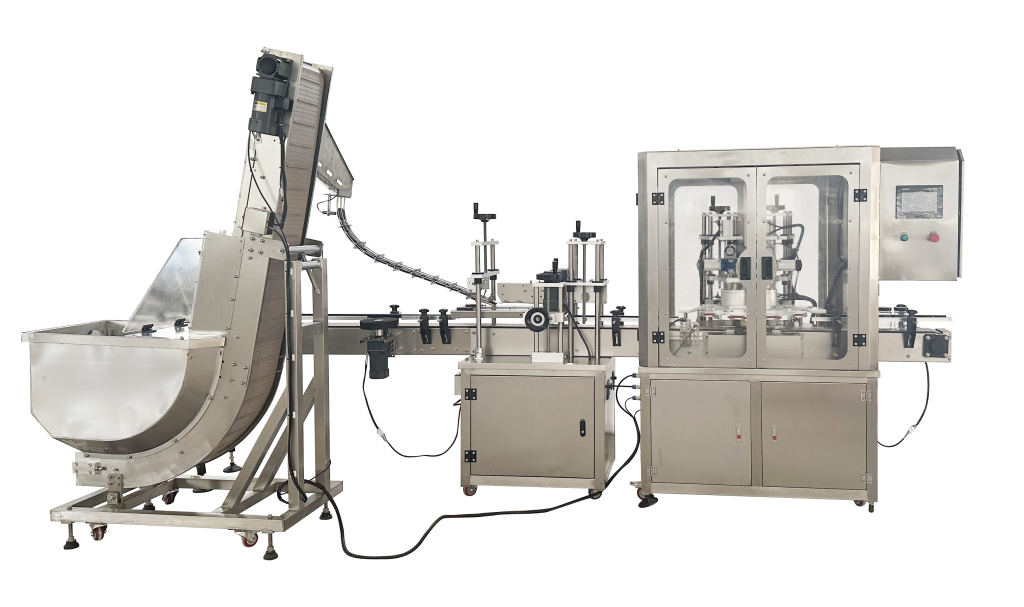

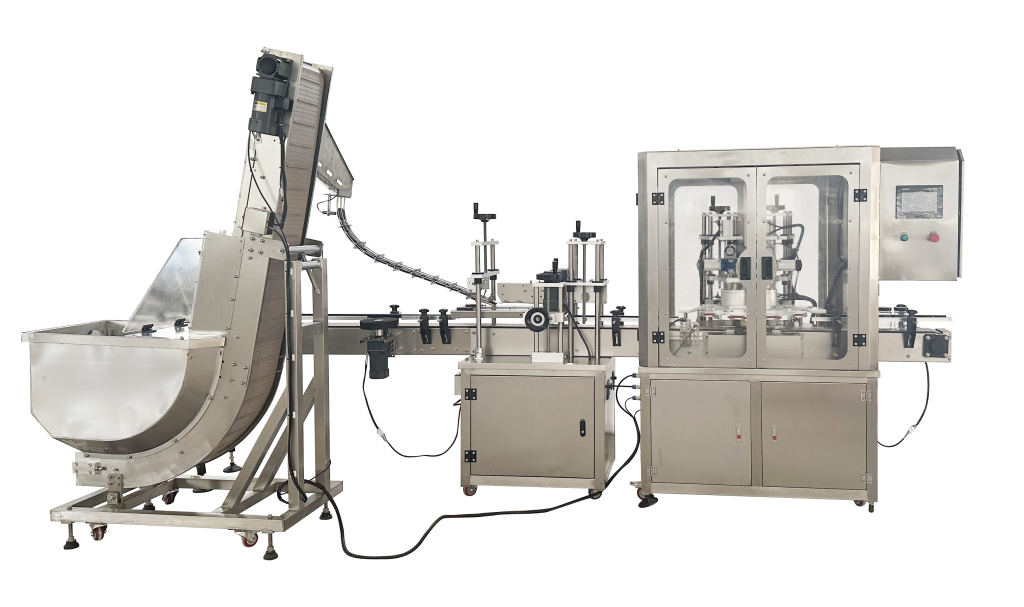

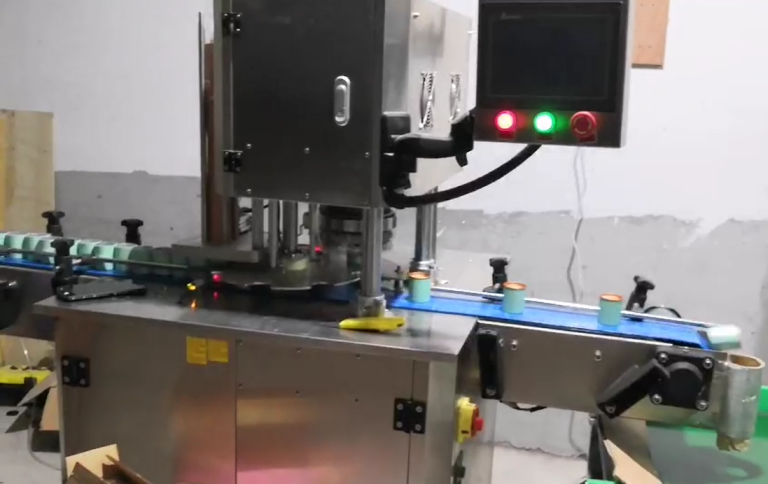

Benefits of Using Automatic Dual Head Servo Candy Bottle Twist Off Capping Machine Automatic dual head servo candy bottle twist off capping machines are revolutionizing the packaging industry by providing a fast, efficient, and reliable solution for capping bottles. These machines are equipped with advanced technology that allows them to…

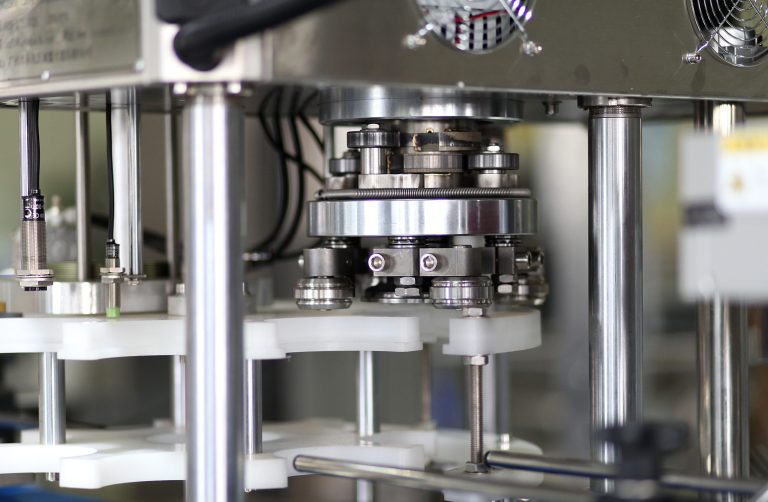

Importance of Regular Maintenance for Can Sealing Machines Can sealing machines are an essential piece of equipment in many industries, including food and beverage, pharmaceuticals, and cosmetics. These machines are used to seal cans securely, ensuring that the contents remain fresh and uncontaminated. However, like any piece of machinery, can…

The Automatic Season Herb Cans Auger Filling Machine is a remarkable innovation in the packaging industry. This Automatic Season Herb Cans Auger Filling Machine is specially designed to handle the filling of season herb cans with efficiency and accuracy. The auger filling mechanism ensures a consistent and precise amount of…

In the world of cookie packaging, the cookies tin container tape around closing machine plays a crucial role. This specialized cookies tin container tape around closing machine is engineered to provide a secure and neat closure for cookies tin containers. The tape around closing mechanism ensures that the containers are…

Benefits of Using Automatic Seamer Machine for Aluminum Beverage Can The automatic seamer machine for aluminum beverage cans is a crucial piece of equipment in the production process of canned beverages. This machine plays a vital role in ensuring that the cans are sealed properly, preventing any leaks or contamination…