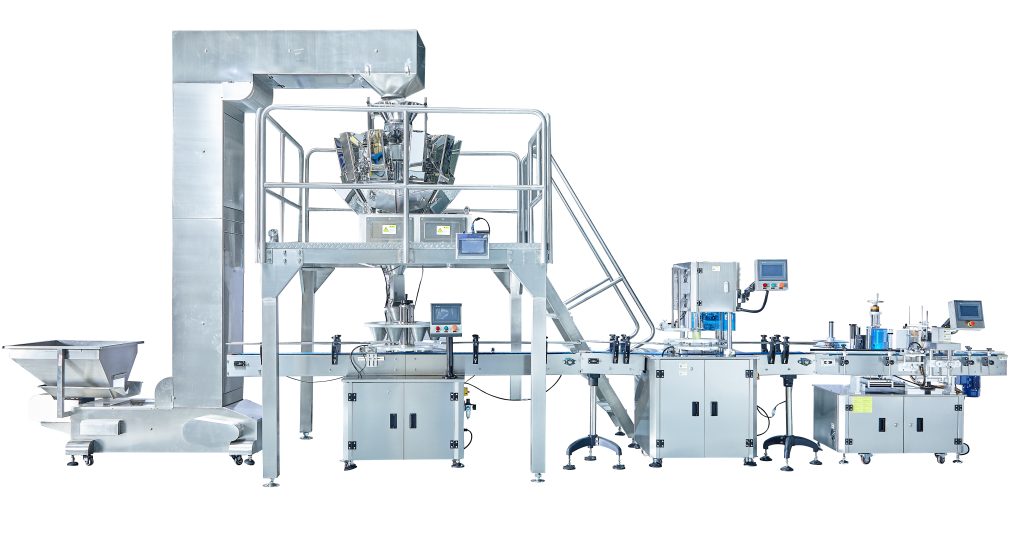

In the fast-paced world of snack production, the fully automatic can packing line for snacks has emerged as a game-changer. This advanced system is transforming the way snacks are packaged, offering efficiency, consistency, and quality like never before.

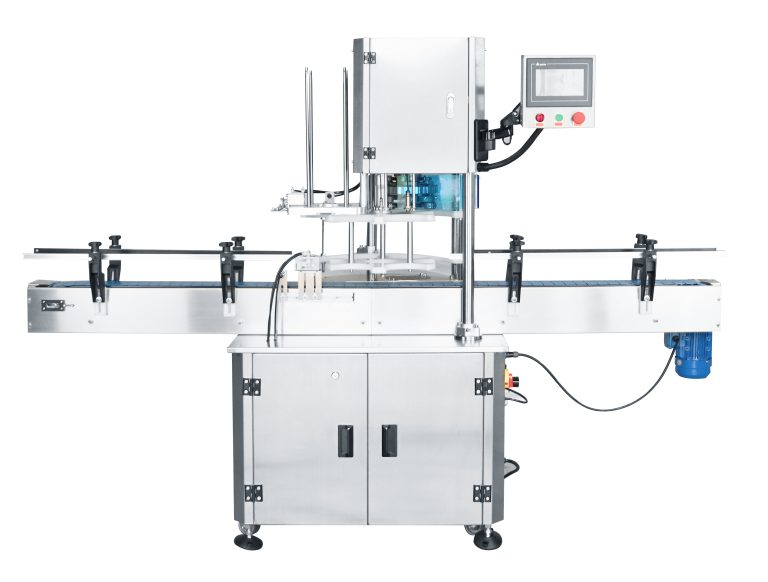

One of the most significant advantages of this packing line is its seamless automation. From the moment the snacks are produced to the final stage of canning and sealing, the process is smooth and uninterrupted. This not only saves time but also minimizes the risk of human error, ensuring that each can is filled accurately and securely.

The speed of the fully automatic can packing line is truly impressive. It can handle a large volume of snacks in a short period, allowing manufacturers to meet the ever-growing demand of consumers. This increased productivity is crucial for businesses to stay competitive in the market.

The quality control aspect is another key feature. Sensors and monitoring systems are integrated throughout the line to detect any flaws or inconsistencies in the packaging. This ensures that only perfect cans reach the shelves, maintaining the brand’s reputation for excellence.

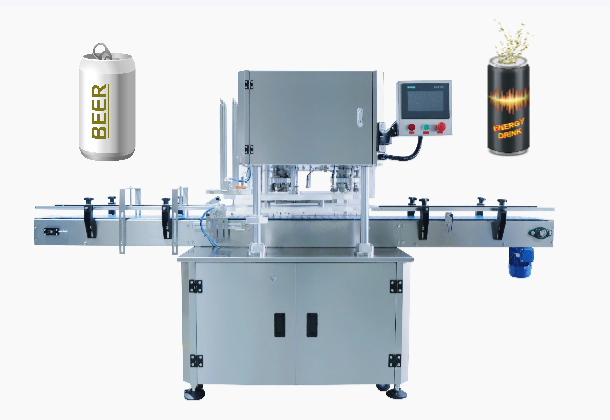

The flexibility of the system is also worth noting. It can accommodate various snack types and sizes, as well as different can designs and labeling requirements. This adaptability makes it suitable for a wide range of snack products and marketing strategies.

Maintenance of the fully automatic can packing line for snacks is made easier with its user-friendly design and accessible components. Regular servicing and upkeep can prolong its lifespan and ensure optimal performance.

In conclusion, the fully automatic can packing line for snacks is a remarkable innovation that is shaping the future of the snack packaging industry. It offers a combination of speed, accuracy, and flexibility that is essential for businesses to thrive in a dynamic marketplace.

Stay tuned to our blogs for more detailed insights and updates on the latest developments in packaging technology!

-768x576.png)