Table of Contents

Benefits of Using Ghee Packaging Machine

Ghee, also known as clarified butter, is a popular ingredient in many cuisines around the world. It is commonly used in Indian, Middle Eastern, and Southeast Asian cooking for its rich flavor and high smoke point. Due to its popularity, the demand for ghee has been steadily increasing, leading to the need for efficient packaging solutions. This is where ghee packaging machines come into play.

Ghee packaging machines are specially designed to streamline the packaging process for ghee manufacturers. These machines are equipped with advanced technology that allows for precise filling, sealing, and labeling of ghee containers. By automating these tasks, ghee packaging machines help to increase productivity, reduce labor costs, and improve overall efficiency.

One of the key benefits of using a ghee packaging machine is the consistency it provides in packaging. Manual packaging processes can lead to variations in the amount of ghee filled in each container, which can affect the quality and presentation of the product. With a ghee packaging machine, manufacturers can ensure that each container is filled with the exact amount of ghee, resulting in a uniform and professional-looking product.

In addition to consistency, ghee packaging machines also help to extend the shelf life of the product. By sealing the containers tightly and preventing exposure to air and moisture, these machines help to preserve the freshness and flavor of the ghee for a longer period of time. This not only benefits the consumers by ensuring that they receive a high-quality product, but also helps manufacturers reduce waste and minimize product spoilage.

Another advantage of using a ghee packaging machine is the flexibility it offers in packaging options. These machines can be customized to accommodate different container sizes, shapes, and materials, allowing manufacturers to package their ghee in a variety of formats. Whether it’s glass jars, plastic containers, or pouches, ghee packaging machines can handle a wide range of packaging requirements, making them a versatile solution for ghee manufacturers.

Furthermore, ghee packaging machines are designed to meet strict hygiene and safety standards. These machines are made from food-grade materials and are equipped with features such as automatic cleaning and sanitization systems to ensure that the ghee is packaged in a clean and sanitary environment. This not only helps to maintain the quality and integrity of the product but also ensures compliance with regulatory requirements.

Overall, ghee packaging machines offer a range of benefits for ghee manufacturers, including increased productivity, consistency in packaging, extended shelf life, packaging flexibility, and adherence to hygiene and safety standards. By investing in a ghee packaging machine, manufacturers can improve their packaging processes, enhance the quality of their products, and ultimately, increase customer satisfaction.

Tips for Choosing the Right Ghee Packaging Machine

Ghee, also known as clarified butter, is a popular ingredient in many cuisines around the world. It is commonly used in Indian, Middle Eastern, and Southeast Asian dishes for its rich flavor and high smoke point. With the increasing demand for ghee in the market, manufacturers are constantly looking for ways to improve their production processes, including packaging.

One of the key components in the ghee packaging process is the packaging machine. Choosing the right ghee packaging machine is crucial for ensuring the quality and safety of the product. There are several factors to consider when selecting a ghee packaging machine, including the type of packaging material, production capacity, and automation level.

When it comes to packaging ghee, it is important to use packaging materials that are suitable for the product. Ghee is a semi-solid at room temperature and can become liquid when heated, so it is essential to use packaging materials that are heat-resistant and leak-proof. Common packaging materials for ghee include glass jars, plastic containers, and pouches. The type of packaging material will depend on the intended shelf life of the product and the target market.

In addition to the packaging material, the production capacity of the ghee packaging machine is another important factor to consider. The production capacity of a packaging machine is typically measured in units per minute or units per hour. It is important to choose a machine that can meet the production demands of your business. If you have a small-scale operation, a semi-automatic or manual packaging machine may be sufficient. However, if you have a large-scale operation, you may need a fully automatic packaging machine to meet the high production volumes.

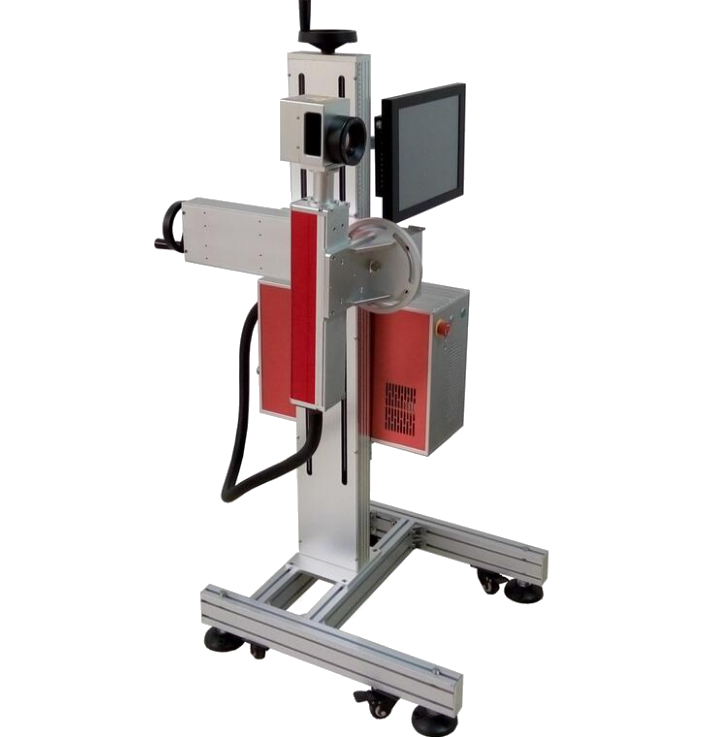

Automation level is another key factor to consider when choosing a ghee packaging machine. Automation can help improve efficiency, reduce labor costs, and ensure consistent packaging quality. Fully automatic packaging machines can handle all aspects of the packaging process, from filling and sealing to labeling and coding. Semi-automatic machines require some manual intervention, such as loading containers or adjusting settings. The level of automation will depend on the specific needs of your business and the available budget.

When selecting a ghee packaging machine, it is also important to consider the technical specifications of the machine. This includes the machine’s dimensions, power requirements, and maintenance needs. It is important to choose a machine that fits within your production facility and can be easily integrated into your existing production line. Additionally, it is important to consider the after-sales support provided by the manufacturer, including warranty coverage and technical support.

In conclusion, choosing the right ghee packaging machine is essential for ensuring the quality and safety of your product. Consider factors such as packaging material, production capacity, automation level, and technical specifications when selecting a packaging machine. By investing in a high-quality packaging machine, you can improve efficiency, reduce costs, and ensure consistent packaging quality for your ghee products.