Table of Contents

Benefits of Using an Automatic Potato Chips Can Sealing Machine

Potato chips are a popular snack enjoyed by people of all ages around the world. Whether you prefer classic salted chips or more adventurous flavors like barbecue or sour cream and onion, there’s no denying the appeal of these crispy, salty treats. For manufacturers and distributors of potato chips, ensuring that their products reach consumers in perfect condition is essential. One way to achieve this is by using an automatic potato chips can sealing machine.

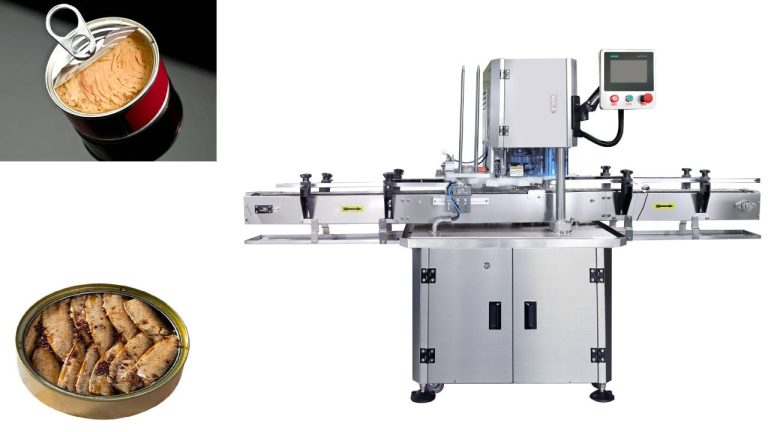

An automatic potato chips can sealing machine is a piece of equipment that is designed to seal cans of potato chips quickly and efficiently. This machine is a valuable asset for companies that produce and package potato chips in cans, as it helps to ensure that the product remains fresh and crispy for longer periods. By sealing the cans tightly, the machine helps to prevent air and moisture from entering, which can cause the chips to become stale and lose their crunchiness.

One of the key benefits of using an automatic potato chips can sealing machine is the speed and efficiency it offers. These machines are capable of sealing hundreds of cans per hour, which can significantly increase productivity and reduce labor costs. With a manual sealing process, workers would need to seal each can individually, which is time-consuming and labor-intensive. By automating this process, companies can save time and resources, allowing them to focus on other aspects of their business.

In addition to speed and efficiency, automatic potato chips can sealing machines also offer a high level of precision and consistency. These machines are programmed to seal cans with a specific amount of pressure and heat, ensuring that each can is sealed correctly every time. This helps to reduce the risk of human error and ensures that the product meets quality standards consistently. By maintaining a consistent seal on every can, companies can build trust with consumers and establish a reputation for delivering high-quality products.

Another benefit of using an automatic potato chips can sealing machine is the improved shelf life of the product. By sealing the cans tightly, the machine helps to protect the chips from exposure to air and moisture, which can cause them to spoil. This extends the shelf life of the product, allowing companies to distribute their potato chips to a wider market and reduce the risk of waste. Consumers can also enjoy fresher, crunchier chips for longer periods, enhancing their overall snacking experience.

Furthermore, automatic potato chips can sealing machines are designed to be user-friendly and easy to operate. Companies can train their employees to use the machine quickly, allowing them to start sealing cans with minimal downtime. This ease of use also reduces the risk of accidents and injuries in the workplace, creating a safer environment for workers.

In conclusion, an automatic potato chips can sealing machine offers numerous benefits for companies in the snack food industry. From increased productivity and efficiency to improved product quality and shelf life, these machines are a valuable investment for any business that produces and packages potato chips in cans. By automating the sealing process, companies can streamline their operations, reduce costs, and deliver a superior product to consumers.

How to Choose the Right Automatic Potato Chips Can Sealing Machine for Your Business

In the food packaging industry, having the right equipment can make all the difference in the efficiency and quality of your products. When it comes to sealing cans of potato chips, an automatic can sealing machine is a must-have for any business looking to streamline their production process. These machines are designed to quickly and efficiently seal cans of various sizes, ensuring that your products are properly sealed and protected from external contaminants.

When choosing the right automatic potato chips can sealing machine for your business, there are several factors to consider. One of the most important considerations is the speed and capacity of the machine. Depending on the size of your operation and the volume of cans you need to seal, you’ll want to choose a machine that can keep up with your production demands. Look for a machine that offers a high sealing speed and can handle a large number of cans per hour to ensure that your production line runs smoothly.

Another important factor to consider is the sealing quality of the machine. The last thing you want is for your products to leak or become contaminated due to a faulty seal. Look for a machine that offers a consistent and reliable sealing process to ensure that your products are properly sealed every time. Some machines even offer features like vacuum sealing to further protect your products from external contaminants.

In addition to speed and sealing quality, you’ll also want to consider the size and design of the machine. Make sure that the machine you choose is compatible with the size and shape of the cans you use for your potato chips. Some machines are designed to handle a specific size or type of can, so be sure to choose a machine that meets your specific needs.

When it comes to maintenance and upkeep, choose a machine that is easy to clean and maintain. Look for a machine that offers easy access to the sealing components for quick and efficient cleaning. Regular maintenance is essential to ensure that your machine continues to operate at peak performance and prolong its lifespan.

Finally, consider the overall cost of the machine, including the initial purchase price and any ongoing maintenance costs. While it’s important to invest in a high-quality machine that meets your production needs, you’ll also want to make sure that it fits within your budget. Compare prices and features from different manufacturers to find the best value for your business.

In conclusion, choosing the right automatic potato chips can sealing machine for your business is essential to ensure the efficiency and quality of your production process. Consider factors like speed, sealing quality, size, design, maintenance, and cost when making your decision. By investing in a high-quality machine that meets your specific needs, you can streamline your production process and ensure that your products are properly sealed and protected.