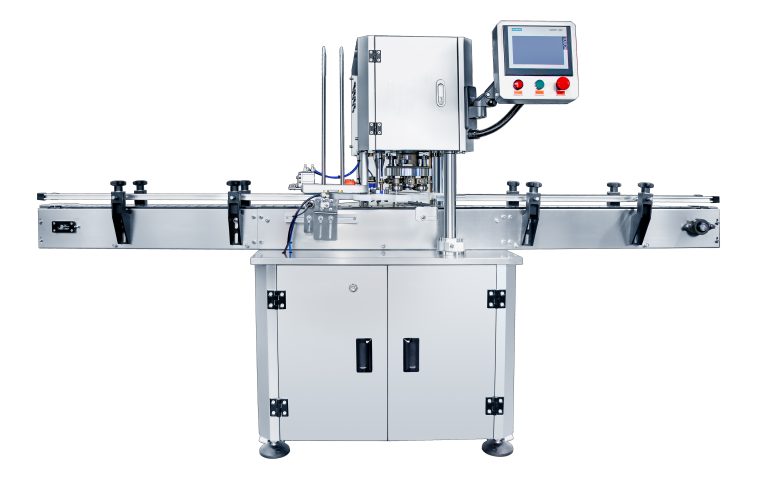

In the world of paper can manufacturing, the Automatic Paper Can Flanging and Cleaning Machine has emerged as a game-changer, redefining efficiency in the production process.

The efficiency of this machine begins with its seamless integration of flanging and cleaning functions. Instead of separate, time-consuming steps, it performs both tasks in one continuous operation, saving valuable production time.

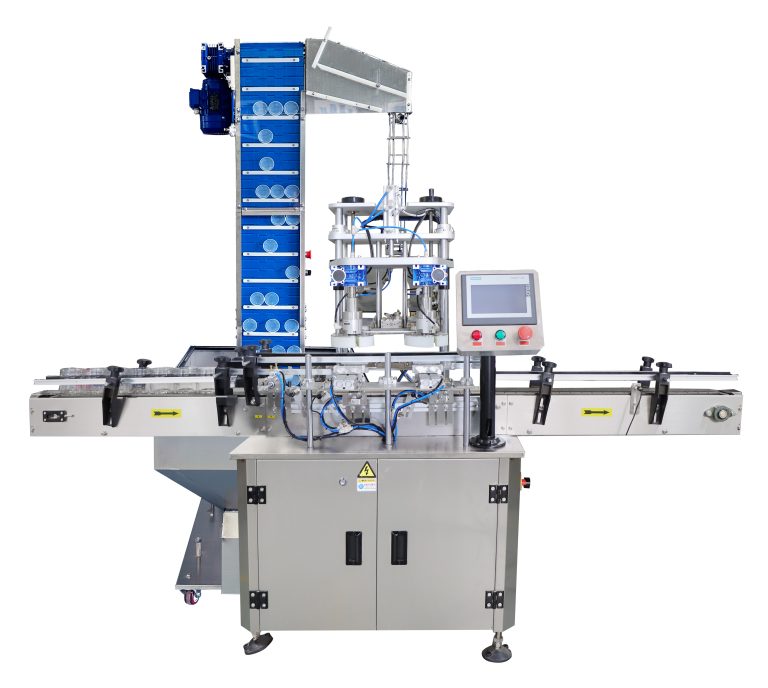

Its high-speed operation is a key factor in enhancing efficiency. The machine is capable of processing a large number of paper cans in a short period, allowing manufacturers to meet tight deadlines and increase output.

Precision is another aspect that contributes to its efficiency. The flanging process is carried out with exactitude, ensuring uniform and well-formed flanges on each paper can. This eliminates the need for rework and reduces material waste.

The cleaning mechanism is equally efficient, thoroughly removing dirt and debris from the cans with minimal effort and maximum effectiveness.

The Automatic Paper Can Flanging and Cleaning Machine also reduces human error. Automated processes eliminate the inconsistencies that can occur with manual operations, resulting in a consistently high-quality output.

Moreover, its ease of use and maintenance further add to its efficiency. Operators can quickly master the machine’s operation, and its reliable design ensures minimal downtime for servicing and repairs.

In conclusion, when you discover the efficiency of the Automatic Paper Can Flanging and Cleaning Machine, you uncover a tool that not only boosts productivity but also raises the quality and reliability of paper can production. It is a true asset for any manufacturing facility looking to stay competitive in the market.