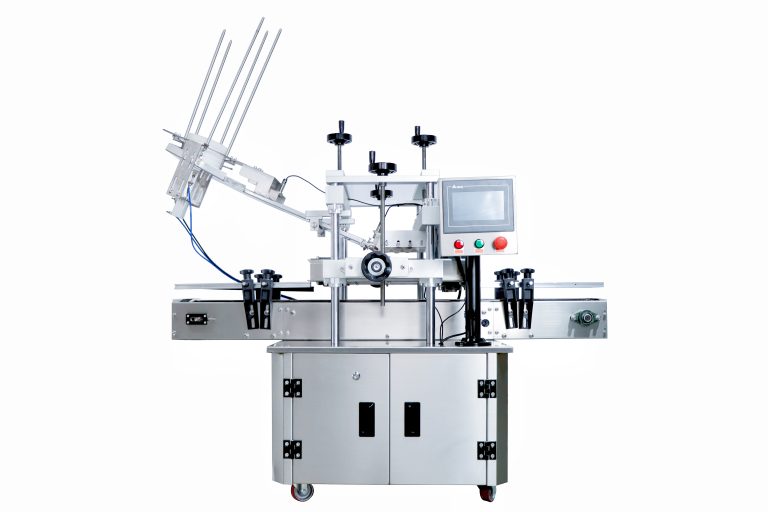

In the world of modern manufacturing and packaging, precision is of paramount importance. The Automatic Single Side Labeling Machine stands out as a remarkable example of achieving this crucial aspect. Let’s embark on a journey to discover the depths of its precision.

The heart of the precision lies in the advanced technology incorporated within these machines. Sophisticated sensors and intelligent control systems work in harmony to ensure that each label is placed with exactitude. Every millimeter counts, and these machines leave no room for error.

The Automatic Single Side Labeling Machine is engineered to handle a wide range of label types and materials, adapting flawlessly to different textures and adhesives. This adaptability ensures that regardless of the label specifications, the application is consistently precise.

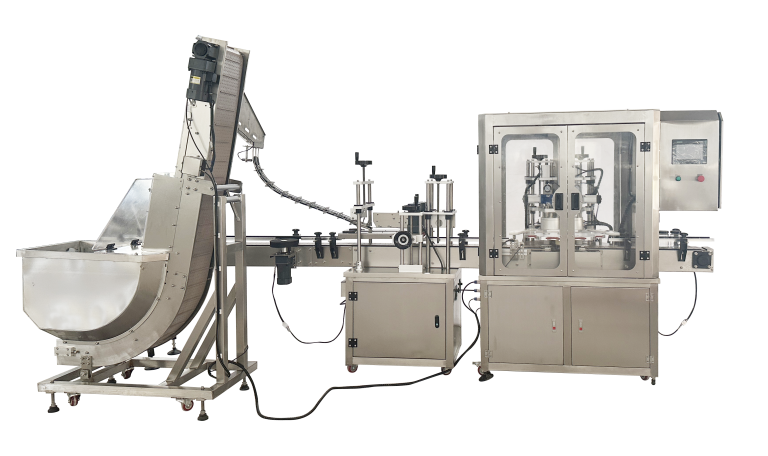

The speed at which the machine operates does not compromise its precision. Even at high production rates, it maintains the accuracy needed to meet the strictest quality standards. This combination of speed and accuracy is a key factor in enhancing productivity without sacrificing quality.

Furthermore, the ability to adjust settings with minute precision allows for customization based on specific product requirements. Whether it’s the position, orientation, or tension of the label, every detail can be fine-tuned to perfection.

The repeatability of the labeling process is another aspect that showcases its precision. Time after time, the machine delivers identical, accurate results, ensuring uniformity across batches of products.

In conclusion, the precision of Automatic Single Side Labeling Machines is not just a feature; it’s a guarantee of quality, efficiency, and customer satisfaction. Discovering this precision opens up new possibilities for businesses seeking excellence in their packaging processes.