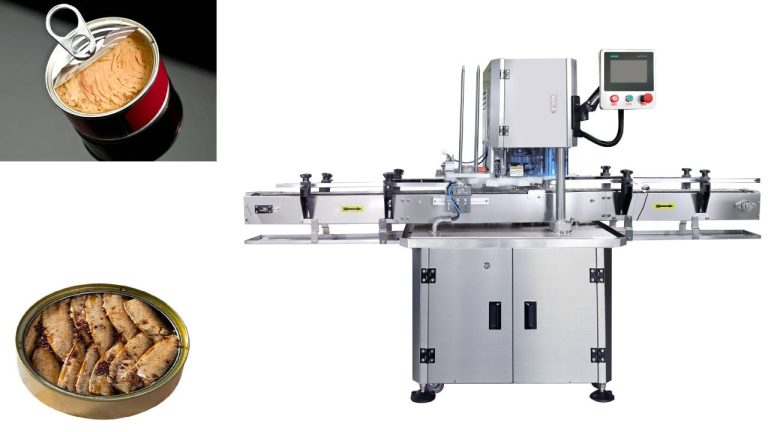

Automatic Vacuum Nitrogen Flushing Can Seamers operate through a precise and sequential process to ensure the highest quality packaging.

The process begins with the cans being placed on the conveyor belt and entering the machine. Once inside, a vacuum pump is activated to extract the air from the can. This creates a vacuum environment, reducing the presence of oxygen that could cause spoilage or degradation of the contents.

Immediately after the vacuum is created, nitrogen gas is injected into the can. The nitrogen displaces the remaining air and fills the void, providing an inert atmosphere that helps preserve the product.

Next, the seaming operation commences. The can lid is precisely positioned over the can’s opening, and the seaming head comes into action. It applies pressure and rotates to form a tight and secure seal, ensuring that the contents are safely contained within.

Throughout the process, sensors and control systems monitor various parameters such as vacuum levels, nitrogen flow, and seaming pressure. This real-time monitoring and adjustment guarantee that each can is processed consistently and meets the required standards of quality and integrity.

The entire operation is automated, with the machine’s programming and mechanical components working in harmony to achieve efficient and reliable can seaming with vacuum nitrogen flushing. This advanced technology ensures that products packaged using these seamers have an extended shelf life and maintain their quality over time.