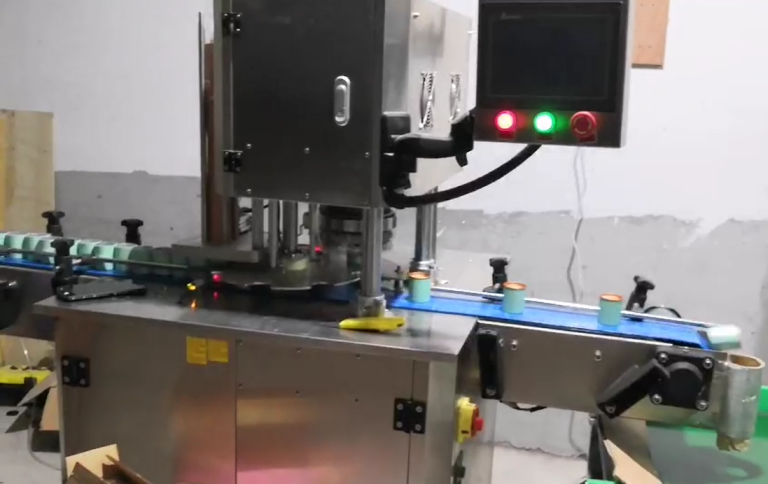

Automatic Double-Head Servo Capping Machines come with several notable features that make them highly efficient and reliable in capping operations.

One of the primary features is the dual-head design. This allows for simultaneous capping of two containers, doubling the production speed and significantly increasing productivity.

The servo technology ensures precise control over the capping process. It accurately regulates the torque, speed, and position of the capping heads, guaranteeing consistent and tight seals on each container.

These machines are often equipped with advanced cap feeding systems. They can handle a variety of cap sizes and types, and ensure a smooth and continuous supply of caps to the capping heads.

Another important feature is the high level of automation. From container loading to capping and unloading, the entire process is automated, minimizing the need for manual intervention and reducing the potential for errors.

They also offer flexibility in terms of the types and sizes of containers they can accommodate. This adaptability makes them suitable for a wide range of products and production requirements.

The machines are typically built with durable materials and components, ensuring a long service life and low maintenance costs.

In addition, they often come with intelligent control systems that provide real-time monitoring and diagnostic capabilities. This allows for quick identification and resolution of any issues that may arise during operation.

Overall, the combination of these key features makes Automatic Double-Head Servo Capping Machines a valuable investment for businesses seeking efficient and high-quality capping solutions.

-768x512.jpg)