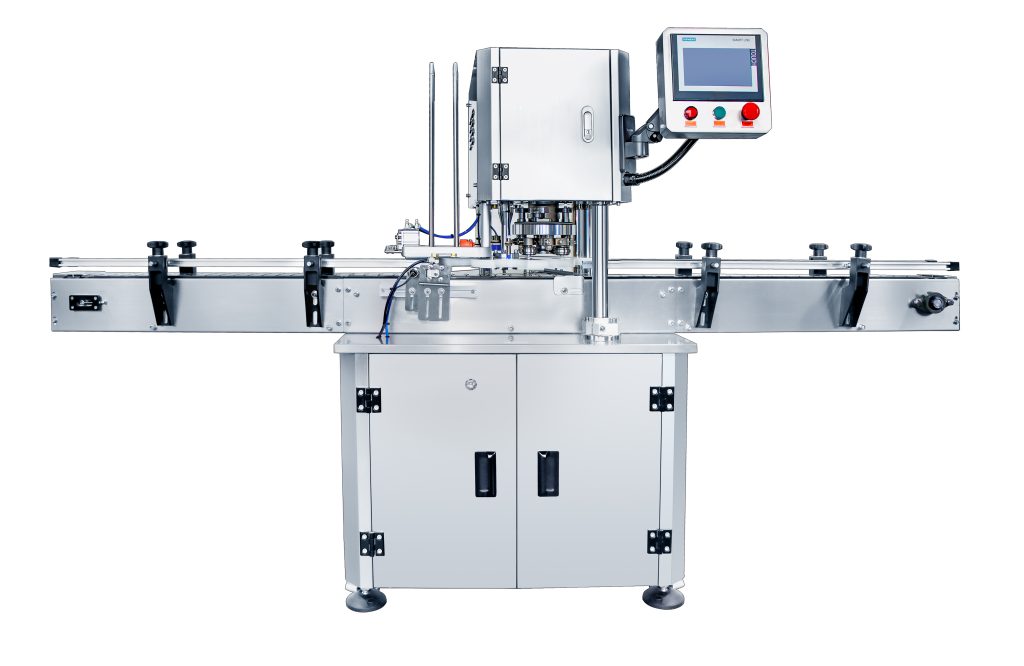

Automatic servo can seamer machines come with several essential features that are worth knowing.

One of the key features is the high level of precision and accuracy in seaming. The servo technology allows for fine-tuned control, ensuring each can is sealed perfectly.

They offer adjustable seaming parameters. This enables operators to customize the sealing process based on the specific requirements of different cans and products.

Fast and efficient operation is another important aspect. These machines can seal a large number of cans in a short time, increasing production output.

The ability to handle various can sizes and shapes with ease is a significant feature. It provides flexibility for manufacturers dealing with diverse product lines.

Advanced safety mechanisms are often incorporated to protect operators and prevent accidents during the seaming process.

The machines are equipped with user-friendly interfaces and control panels, making them simple to operate and monitor.

Some models also have intelligent error detection and diagnostic systems. This helps in quickly identifying and resolving any issues that may arise.

Durability and low maintenance requirements are crucial features as well. They ensure long-term reliable performance and minimize downtime for repairs and servicing.

In summary, these key features make automatic servo can seamer machines a valuable asset in the packaging industry, offering quality, efficiency, and flexibility.