Milk Powder Can Packaging Line, include Can Rotary Infeed, Automatic Round Bottle Jars Cans Labeling Machine, Empty Can UV Sterilization And Cleaning Machine, Automatic Round Can Sealing Machine, Automatic Single Head Powder Auger Filling Machine, Automatic Plastic Press Lid Capping Machine,Outfeed Rotary Tables.

This machine is widely used to pack canned milk powder, coffee powder, jaggery powder, etc.It is suitable for plastic/metal cans packing and widely used in food, pharmaceutical, chemical, commodity industries, etc.

Can Rotary Infeed can accommodate a large number of cans at a time, automatically sorting into the conveyor belt of the packaging line, saving labor costs, improving production line automation, and thus improving production efficiency.

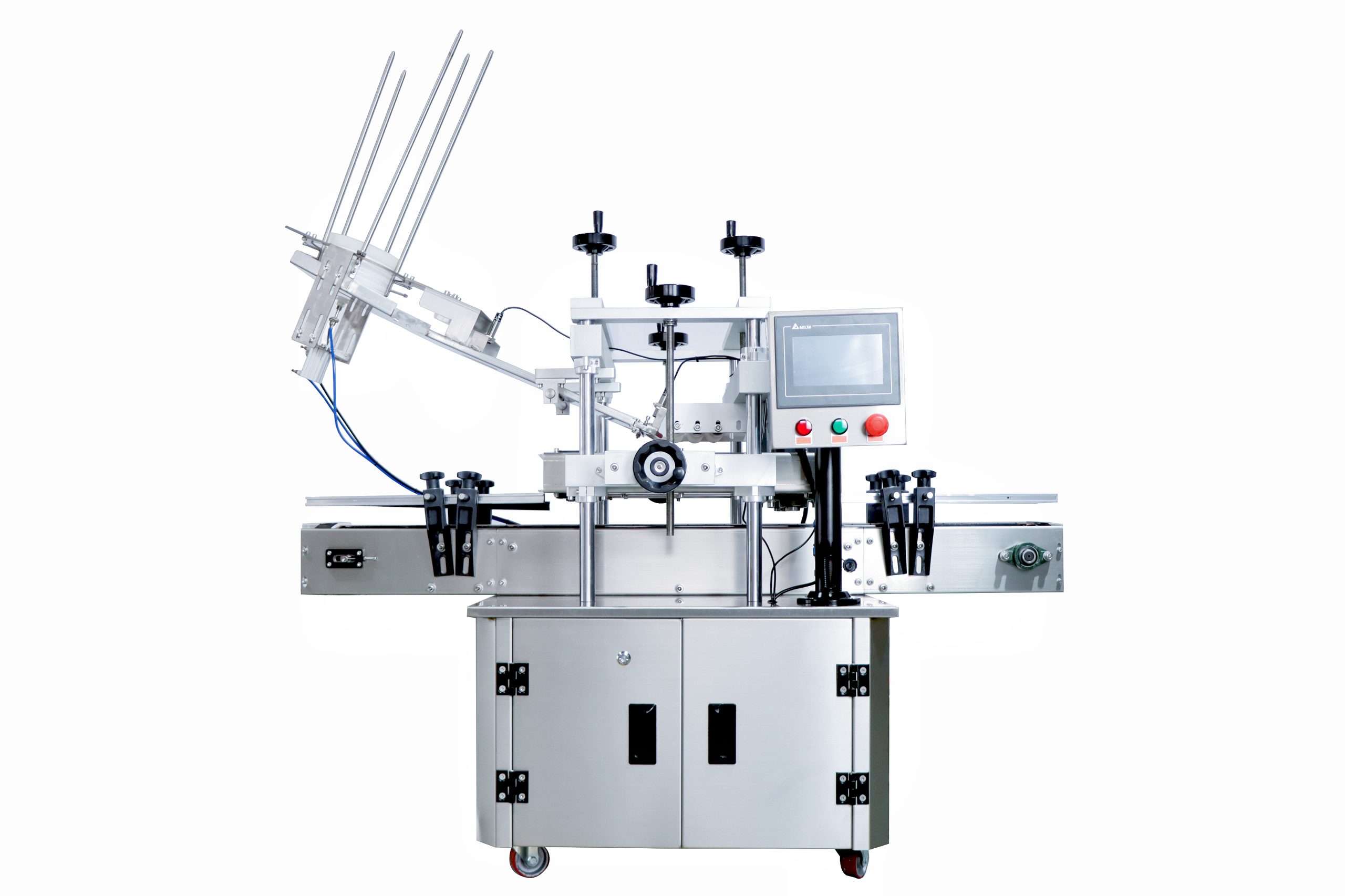

Automatic Round Bottle Jars Cans Labeling Machine is designed for can body. Have functions of automatic stop, counting, power saving. Suitable for bottles, beer cans, and other cylindrical containers.

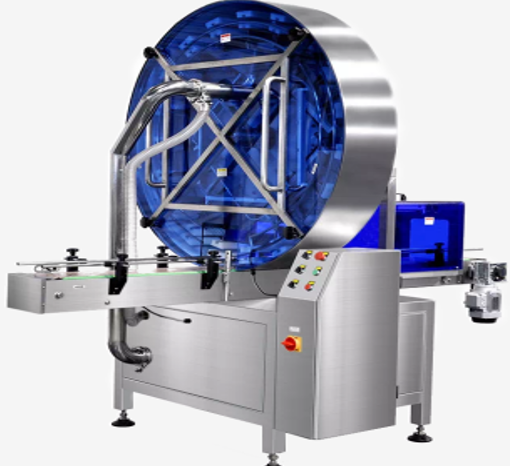

Empty Can UV Sterilization And Cleaning Machine can hold a large number of cans at one time and automatically arrange them on the conveyor belt of the packaging line, saving labor costs, improving the automation of the production line, and improving production efficiency.

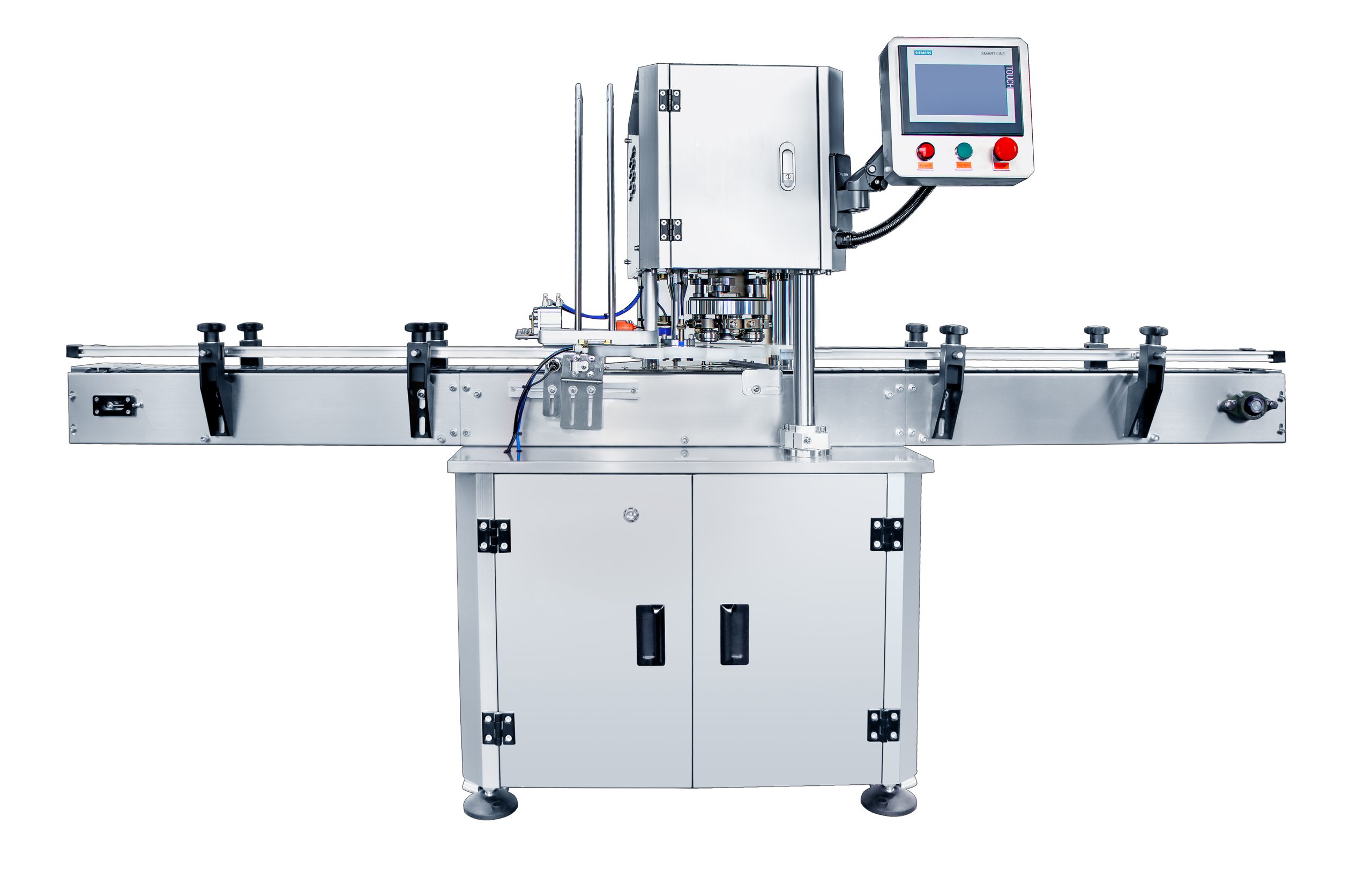

Automatic Round Can Sealing Machine has advantages that it can work precisely and automatically.It is not hard to operate and work stably.It is the ideal choice for sealing ring pull cans,paper cans etc.It gets a lot of popularity from the manufacturers producing tea,juice,pet food etc.

Automatic Single Head Powder Auger Filling Machine is suitable for packaging powder granular materials, such as milk powder, feed, rice flour, various powders, sugar, coffee, monosodium glutamate, solid drinks, glucose, etc.

Automatic Plastic Press Lid Capping Machine is applicable for capping all kinds of round and square cans including PET plastic can, metal can, aluminum can and paper cans.

Outfeed Rotary Tables can accommodate many cans at a time, automatically collecting the cans of the packaging line, saving labor costs, improving production line automation, and thus improving production efficiency.Used at the end of the packaging line according to customer requirements.