Table of Contents

Benefits of Using Can Seamer Machines for Small Batch Production

Can seamer machines are essential equipment for sealing cans in various industries, including food and beverage, pharmaceuticals, and cosmetics. These machines offer a fast and efficient way to seal cans, ensuring product freshness and preventing contamination. In this article, we will discuss the different types and market segments of can seamer machines, focusing on the benefits of using them for small batch production.

There are several types of can seamer machines available on the market, each designed for specific applications and production requirements. The most common types include manual, semi-automatic, and fully automatic can seamers. Manual can seamers are operated by hand and are suitable for small-scale production or home use. They require more labor and time compared to semi-automatic and fully automatic machines but are cost-effective for small batch production.

Semi-automatic can seamers are partially automated machines that require some manual intervention to load and unload cans. These machines are ideal for medium-scale production and offer a good balance between speed and cost. Fully automatic can seamers, on the other hand, are fully automated machines that can seal cans without any manual intervention. These machines are suitable for high-volume production and offer the highest level of efficiency and productivity.

In terms of market segments, can seamer machines are widely used in the food and beverage industry for sealing cans of various products, including fruits, vegetables, soups, sauces, and beverages. They are also used in the pharmaceutical industry for sealing cans of medicines and supplements, as well as in the cosmetics industry for sealing cans of beauty and skincare products. Can seamer machines are versatile and can be customized to meet the specific requirements of different industries and products.

One of the main benefits of using can seamer machines for small batch production is their efficiency and speed. These machines can seal cans quickly and accurately, allowing for faster production and turnaround times. This is especially important for small businesses or startups that need to meet tight deadlines and deliver products to customers on time. Can seamer machines also help reduce labor costs and increase productivity, as they require less manual intervention compared to manual sealing methods.

Another benefit of using can seamer machines for small batch production is their consistency and reliability. These machines are designed to seal cans with precision and accuracy, ensuring a tight and secure seal every time. This helps maintain product freshness and quality, as well as prevent contamination and spoilage. Consistent sealing also helps improve product shelf life and customer satisfaction, as customers can trust that the products they purchase are properly sealed and safe to consume.

In conclusion, can seamer machines are essential equipment for sealing cans in various industries, offering a fast and efficient way to seal cans and ensure product freshness and quality. There are different types of can seamer machines available on the market, each designed for specific applications and production requirements. Using can seamer machines for small batch production offers several benefits, including efficiency, speed, consistency, and reliability. These machines help reduce labor costs, increase productivity, and improve product quality, making them a valuable investment for small businesses and startups.

Exploring Different Types of Can Seamer Machines for Various Packaging Needs

Can seamer machines are essential equipment in the packaging industry, used to seal cans with lids to ensure product freshness and safety. There are various types of can seamer machines available in the market, each designed for specific packaging needs. Understanding the different types and market segments of can seamer machines can help businesses choose the right equipment for their production requirements.

One of the most common types of can seamer machines is the manual can seamer. This type of machine requires operators to manually place the lid on the can and activate the seaming process. Manual can seamers are ideal for small-scale production or for businesses with limited budget constraints. They are simple to operate and maintain, making them a popular choice for start-up companies or artisanal producers.

For medium to large-scale production, businesses may opt for semi-automatic can seamer machines. These machines are equipped with automated lid placement and seaming processes, reducing the need for manual labor and increasing production efficiency. Semi-automatic can seamers are suitable for businesses looking to increase their production capacity without investing in fully automated equipment.

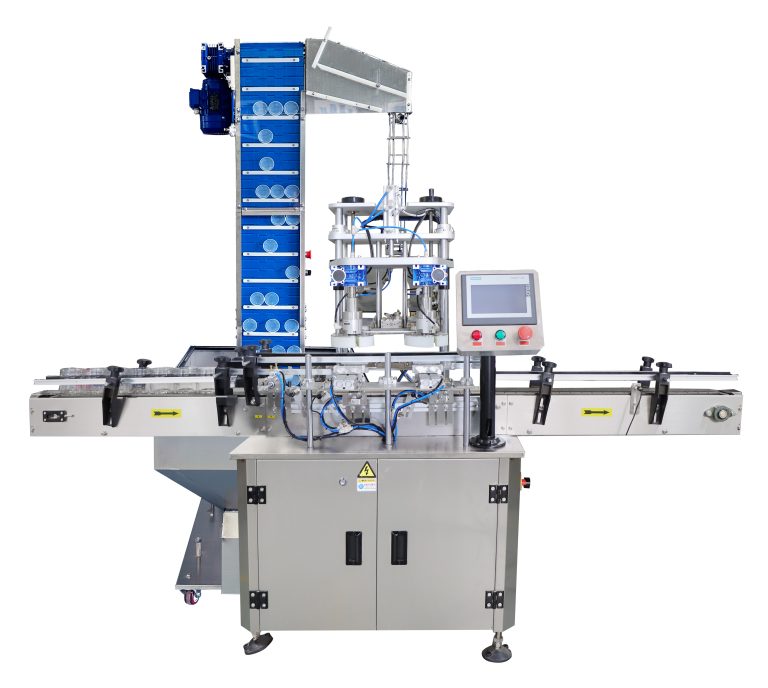

Fully automatic can seamer machines are the most advanced type of equipment available in the market. These machines are capable of handling high-speed production lines with minimal human intervention. Fully automatic can seamers are equipped with advanced technology, such as servo motors and touch screen controls, to ensure precise and consistent sealing of cans. They are ideal for large-scale production facilities that require high output and efficiency.

In addition to the different types of can seamer machines, there are also various market segments that cater to specific packaging needs. For example, the food and beverage industry often requires can seamer machines that are capable of sealing cans with different types of lids, such as easy-open or peel-off lids. These machines are designed to accommodate various lid sizes and materials to meet the specific requirements of food and beverage manufacturers.

The pharmaceutical industry also has unique packaging needs that require specialized can seamer machines. Pharmaceutical can seamers are designed to meet strict regulatory standards for sealing medication containers. These machines are equipped with features such as clean-in-place systems and validation documentation to ensure product safety and compliance with industry regulations.

Another market segment for can seamer machines is the pet food industry. Pet food manufacturers require can seamers that can handle a wide range of can sizes and materials, as well as different types of pet food products, such as wet or dry food. Can seamer machines for the pet food industry are designed to withstand harsh operating conditions and ensure the integrity of the product during storage and transportation.

Overall, understanding the different types and market segments of can seamer machines is essential for businesses looking to invest in packaging equipment. By choosing the right type of machine that meets their production requirements and packaging needs, businesses can improve efficiency, reduce costs, and ensure the quality and safety of their products. Whether it’s a manual, semi-automatic, or fully automatic can seamer machine, there is a wide range of options available to suit every business’s needs in the packaging industry.

Understanding Market Segments and Trends in Can Seamer Machine Industry

Can seamer machines are essential equipment in the packaging industry, used to seal cans with lids to ensure product freshness and safety. These machines come in various types and are designed to cater to different market segments based on the specific needs of the industry. Understanding the types and market segments of can seamer machines is crucial for businesses looking to invest in this equipment.

One of the most common types of can seamer machines is the manual can seamer. This type of machine requires operators to manually place the lid on the can and activate the seaming process. Manual can seamers are ideal for small-scale operations or businesses with limited production volumes. They are cost-effective and easy to operate, making them suitable for startups or businesses looking to test the market before investing in more advanced equipment.

On the other end of the spectrum are automatic can seamer machines, which are designed for high-volume production lines. These machines are fully automated and can seal hundreds of cans per minute, significantly increasing production efficiency. Automatic can seamers are equipped with advanced features such as lid feeding systems, seam monitoring sensors, and touch screen controls, making them ideal for large-scale operations in industries such as food and beverage, pharmaceuticals, and cosmetics.

Semi-automatic can seamer machines fall somewhere in between manual and automatic machines. These machines require operators to place the lid on the can, but the seaming process is automated. Semi-automatic can seamers are suitable for businesses with moderate production volumes that require a balance between efficiency and cost-effectiveness. They offer a higher level of automation compared to manual machines while still being more affordable than automatic machines.

In addition to the different types of can seamer machines, the market for these machines is segmented based on industry verticals. The food and beverage industry is one of the largest consumers of can seamer machines, with applications in sealing cans of fruits, vegetables, soups, and beverages. The pharmaceutical industry also relies on can seamer machines to seal medication containers, ensuring product safety and integrity.

The cosmetics industry is another significant market segment for can seamer machines, used to seal cans of creams, lotions, and other beauty products. These machines are designed to meet the specific requirements of the cosmetics industry, such as sealing delicate containers without damaging the product inside. Other industries that use can seamer machines include the automotive industry for sealing lubricants and chemicals, and the pet food industry for sealing cans of pet food.

As the packaging industry continues to evolve, so do the types and market segments of can seamer machines. Manufacturers are constantly innovating to meet the changing needs of different industries, such as developing machines with higher speeds, improved sealing accuracy, and compatibility with a wide range of can sizes and materials. Businesses looking to invest in can seamer machines should consider their production requirements, industry vertical, and budget to choose the right type of machine that will help them achieve their production goals efficiently and cost-effectively.

In conclusion, understanding the types and market segments of can seamer machines is essential for businesses in the packaging industry. Whether you are a small startup or a large-scale manufacturer, there is a can seamer machine that will meet your production needs. By choosing the right type of machine for your industry vertical and production volume, you can improve efficiency, ensure product quality, and stay competitive in the market.