In the highly competitive world of the spice industry, one company managed to achieve a remarkable feat – boosting their output by an astonishing 200% with the implementation of Automatic Auger Fillers.

The spice company, previously struggling with slow and inconsistent filling processes, was facing challenges in meeting the growing demand for their products. That’s when they decided to invest in Automatic Auger Fillers.

The first major advantage of these fillers was their speed. The auger mechanism enabled rapid filling of spice containers, allowing the company to process a significantly higher volume of products in a shorter period.

Precision was another key factor. The Automatic Auger Fillers ensured that each container received the exact amount of spices, eliminating variations in quantity and maintaining the quality and consistency of their products.

The fillers also reduced the amount of spillage and waste during the filling process. This not only saved on raw materials but also contributed to a cleaner and more organized production floor.

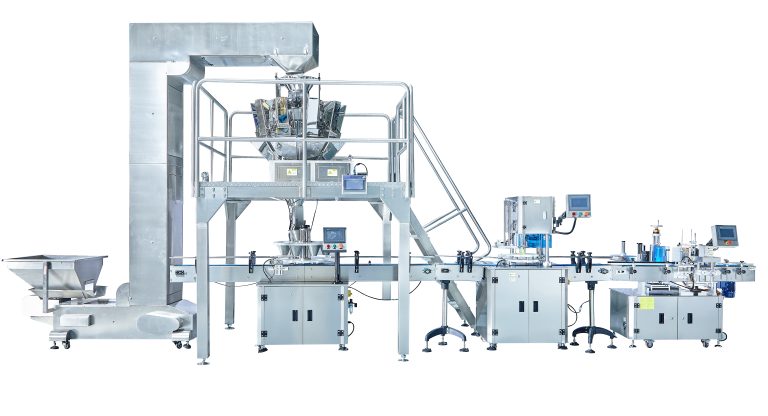

Moreover, the integration of the Automatic Auger Fillers into the existing production line was seamless. The company didn’t have to undergo major disruptions or extensive retooling, which helped minimize downtime and start reaping the benefits quickly.

The improved efficiency led to shorter lead times, allowing the company to fulfill orders promptly and satisfy their customers’ expectations. This, in turn, enhanced their reputation in the market and attracted more business.

The success story of this spice company serves as a prime example of how innovative technologies like Automatic Auger Fillers can transform a business, driving growth and competitiveness in a challenging industry.