Table of Contents

Food Packaging Industry

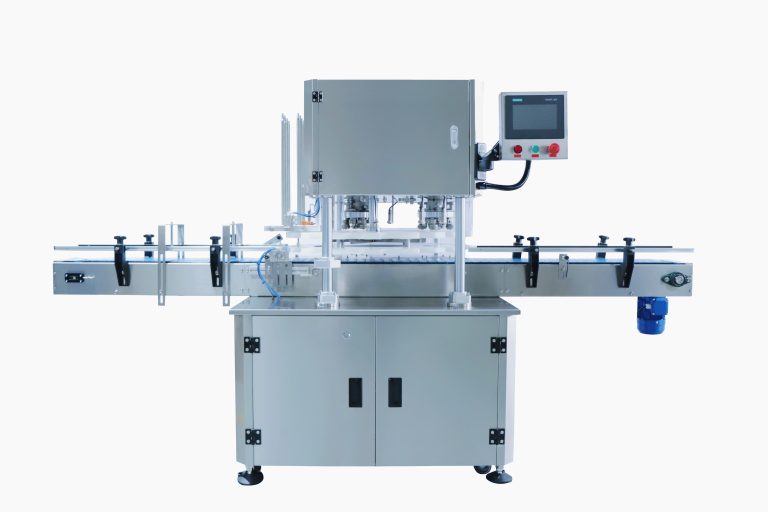

In the food packaging industry, can sealing machines play a crucial role in ensuring the safety and freshness of canned products. These machines are used to seal cans with lids, creating an airtight seal that helps to preserve the contents inside. Can sealing machines are commonly used in industries such as food and beverage, pharmaceuticals, and chemicals.

One of the key benefits of using a can sealing machine is that it helps to extend the shelf life of canned products. By creating an airtight seal, these machines prevent air and moisture from entering the can, which can lead to spoilage and contamination. This is especially important for perishable goods such as fruits, vegetables, and meats, which need to be preserved for long periods of time.

Can sealing machines are also used to maintain the quality and freshness of canned products. By sealing the cans tightly, these machines help to prevent oxidation and exposure to light, which can degrade the quality of the contents inside. This is particularly important for sensitive products such as oils, sauces, and beverages, which can easily spoil if not properly sealed.

In addition to preserving the quality and freshness of canned products, can sealing machines also help to improve the efficiency of the packaging process. These machines are capable of sealing hundreds of cans per minute, making them ideal for high-volume production lines. This not only helps to increase productivity but also reduces the risk of human error, ensuring that each can is sealed correctly and securely.

Can sealing machines come in a variety of sizes and configurations to suit different production needs. Some machines are designed for small-scale operations, while others are capable of sealing large industrial-sized cans. Additionally, can sealing machines can be customized to accommodate different types of lids and cans, making them versatile and adaptable to a wide range of packaging requirements.

Overall, can sealing machines are an essential tool in the food packaging industry, helping to ensure the safety, quality, and freshness of canned products. By creating an airtight seal, these machines help to extend the shelf life of perishable goods, maintain the quality of sensitive products, and improve the efficiency of the packaging process. Whether used in food and beverage, pharmaceuticals, or chemicals, can sealing machines play a vital role in the production and distribution of canned products.

Beverage Industry

In the beverage industry, can sealing machines play a crucial role in ensuring the quality and safety of canned beverages. These machines are used to seal cans with lids, creating an airtight seal that helps preserve the freshness and flavor of the contents inside. Can sealing machines are commonly used in industries such as soft drinks, beer, energy drinks, and other canned beverages.

One of the key benefits of using a can sealing machine is that it helps prevent contamination and spoilage of the product. By creating a secure seal on the can, these machines help protect the contents from exposure to air, moisture, and other contaminants that can affect the quality of the beverage. This is especially important in industries where product quality and consistency are paramount.

Can sealing machines are also used to enhance the shelf life of canned beverages. By creating an airtight seal, these machines help extend the freshness of the product, allowing it to be stored for longer periods without compromising its quality. This is particularly important for beverages that have a longer shelf life or are intended for distribution to a wider market.

In addition to preserving the quality of the product, can sealing machines also help improve the efficiency of the packaging process. These machines are designed to seal cans quickly and accurately, reducing the risk of human error and ensuring a consistent seal on each can. This not only helps streamline the production process but also helps reduce waste and improve overall productivity.

Can sealing machines come in a variety of sizes and configurations to accommodate different production needs. Some machines are designed for high-speed production lines, while others are more suitable for smaller-scale operations. Regardless of the size or capacity, these machines are essential for ensuring the quality and safety of canned beverages in the industry.

Furthermore, can sealing machines are equipped with advanced technology and features to meet the specific requirements of the beverage industry. Some machines are capable of sealing different types of lids, such as aluminum or plastic, while others are designed to handle various can sizes and shapes. This versatility allows manufacturers to customize their packaging process to meet the demands of their product line.

Overall, can sealing machines are an essential component of the beverage industry, helping to ensure the quality, safety, and efficiency of canned beverages. By creating a secure seal on each can, these machines help protect the contents from contamination and spoilage, extend the shelf life of the product, and improve the overall packaging process. With their advanced technology and versatility, can sealing machines are a valuable asset for manufacturers in the beverage industry looking to maintain high standards of quality and consistency in their products.