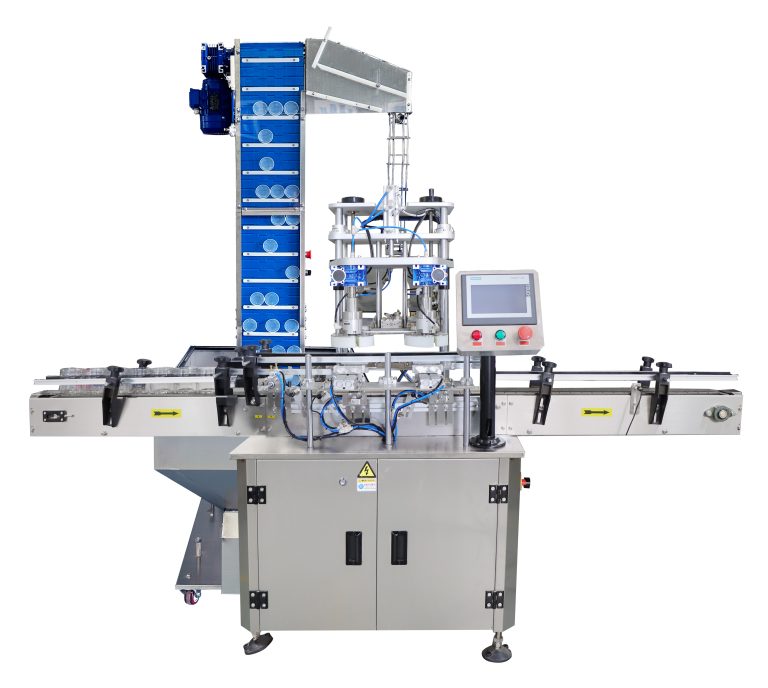

In the ever-evolving world of packaging, innovative sealing solutions are crucial to meet the demands of quality, efficiency, and product preservation. The semi-automatic simple nitrogen can sealing machine stands out as a remarkable advancement in this field.

This machine represents a fusion of simplicity and cutting-edge technology. Its semi-automatic operation provides a balance that combines the speed and accuracy of mechanization with the flexibility and oversight of human intervention.

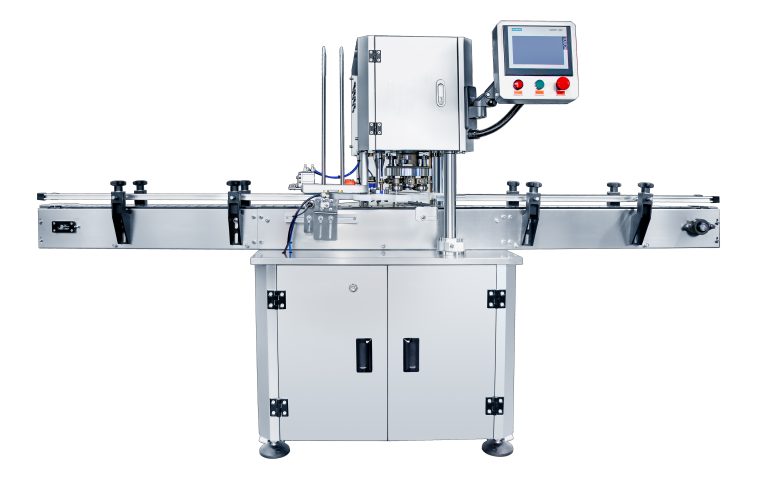

The nitrogen can sealing feature is a game-changer. Nitrogen, an inert gas, helps create an environment within the cans that slows down deterioration and oxidation. This not only prolongs the shelf life of the contents but also ensures that the products maintain their freshness and quality.

The simplicity of the design doesn’t compromise on functionality. The machine is engineered to be user-friendly, allowing operators to quickly master its operation with minimal training. This ease of use translates to reduced setup times and seamless integration into existing packaging lines.

The semi-automatic simple nitrogen can sealing machine also offers consistency in sealing. Each can is sealed with precision, minimizing the risk of leaks or compromised seals. This reliability leads to fewer rejects and higher customer satisfaction.

Furthermore, its adaptability is notable. It can handle a variety of can sizes and shapes, making it suitable for a diverse range of products and packaging needs.

In summary, the semi-automatic simple nitrogen can sealing machine is an innovative sealing solution that brings together simplicity, efficiency, and quality. It is a testament to the continuous progress in the packaging industry, offering businesses a reliable and effective tool to enhance their packaging processes and product offerings.