Table of Contents

Benefits of Using Milk Powder Tin Can Cap Pressing Machine

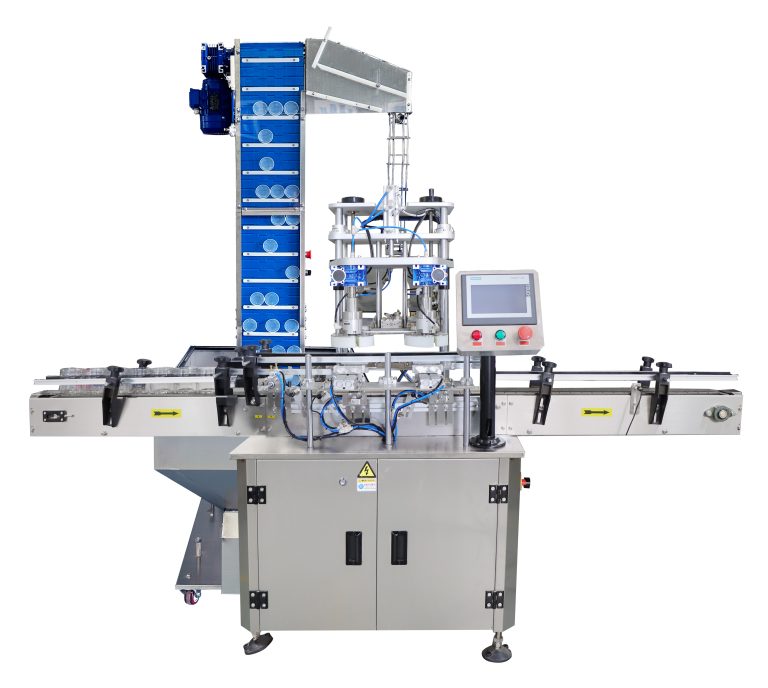

Milk powder tin can cap pressing machines are essential equipment in the dairy industry for sealing tin cans of milk powder securely. These machines offer numerous benefits that make them indispensable for dairy manufacturers. One of the primary advantages of using a milk powder tin can cap pressing machine is the efficiency it brings to the production process. These machines are designed to seal tin cans quickly and accurately, saving time and labor costs for manufacturers.

In addition to efficiency, milk powder tin can cap pressing machines also ensure the quality and safety of the product. By sealing tin cans tightly, these machines prevent contamination and spoilage, extending the shelf life of the milk powder. This is crucial for maintaining the freshness and nutritional value of the product, as well as meeting regulatory standards for food safety.

Furthermore, milk powder tin can cap pressing machines are versatile and can be customized to meet the specific needs of different dairy manufacturers. Whether it’s adjusting the sealing pressure, speed, or cap size, these machines can be tailored to ensure optimal performance and consistency in sealing tin cans. This level of customization allows manufacturers to produce high-quality milk powder products that meet consumer expectations.

Another benefit of using a milk powder tin can cap pressing machine is the cost savings it offers in the long run. By automating the sealing process, manufacturers can reduce the risk of human error and minimize product waste. This not only improves the overall efficiency of the production line but also helps to lower operational costs and increase profitability.

Moreover, milk powder tin can cap pressing machines are easy to operate and maintain, making them user-friendly for dairy manufacturers. With minimal training, operators can quickly learn how to use these machines effectively, ensuring smooth and uninterrupted production. Additionally, regular maintenance and servicing of these machines can help prolong their lifespan and prevent breakdowns, further reducing downtime and production losses.

Overall, the benefits of using a milk powder tin can cap pressing machine are clear. From improving efficiency and product quality to reducing costs and ensuring safety, these machines play a crucial role in the dairy industry. By investing in this essential equipment, dairy manufacturers can streamline their production process, enhance product consistency, and ultimately, meet the growing demand for high-quality milk powder products in the market.

In conclusion, milk powder tin can cap pressing machines offer a wide range of benefits that make them indispensable for dairy manufacturers. With their efficiency, quality assurance, versatility, cost savings, and user-friendly features, these machines are essential for sealing tin cans of milk powder securely and consistently. By incorporating this equipment into their production line, dairy manufacturers can enhance their operations, meet consumer expectations, and stay competitive in the market.

How to Choose the Right Milk Powder Tin Can Cap Pressing Machine for Your Business

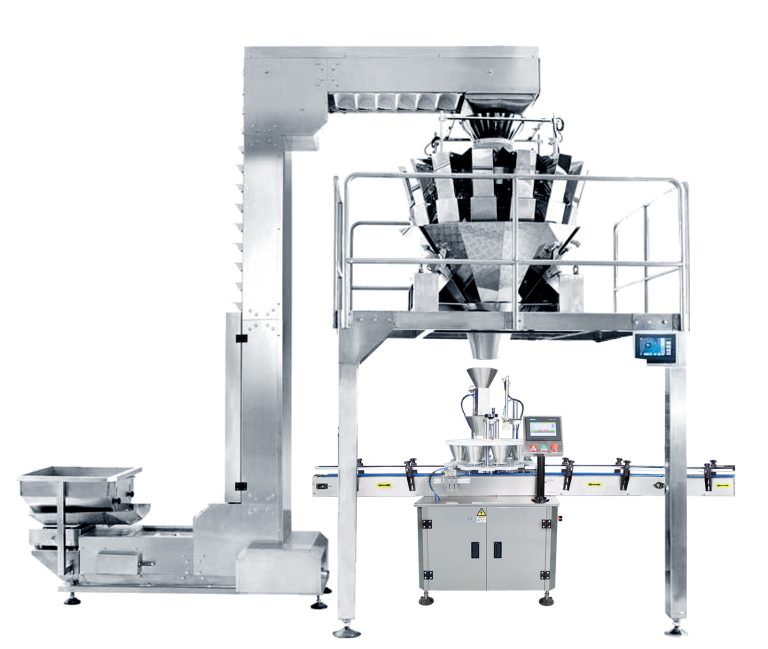

When it comes to packaging milk powder, one of the most important machines you will need is a tin can cap pressing machine. This machine is essential for sealing the cans and ensuring that the product inside remains fresh and uncontaminated. However, with so many options available on the market, choosing the right milk powder tin can cap pressing machine for your business can be a daunting task. In this article, we will discuss some key factors to consider when selecting a tin can cap pressing machine to meet your business needs.

First and foremost, it is important to consider the size and capacity of the machine. The size of the machine will depend on the volume of production in your business. If you have a small-scale operation, a compact machine with a lower capacity may be sufficient. However, if you have a larger production volume, you will need a machine with a higher capacity to meet your needs. It is essential to choose a machine that can handle the volume of cans you need to seal efficiently.

Another important factor to consider is the speed and efficiency of the machine. A fast and efficient machine can help increase productivity and reduce production time. Look for a machine that can seal cans quickly and accurately to ensure that your production line runs smoothly. Additionally, consider the ease of operation and maintenance of the machine. A user-friendly machine that is easy to operate and maintain can help reduce downtime and increase overall efficiency in your production process.

Furthermore, it is crucial to consider the quality and durability of the machine. Investing in a high-quality machine will ensure that it lasts for a long time and provides consistent performance. Look for a machine made from durable materials that can withstand the rigors of daily use in a production environment. Additionally, consider the reputation of the manufacturer and read reviews from other customers to ensure that you are investing in a reliable and reputable machine.

In addition to the factors mentioned above, it is also important to consider the cost of the machine. Set a budget for your purchase and compare prices from different manufacturers to find a machine that offers the best value for your money. Keep in mind that while it is important to stay within budget, it is also essential to prioritize quality and performance when choosing a milk powder tin can cap pressing machine for your business.

In conclusion, choosing the right milk powder tin can cap pressing machine for your business is a crucial decision that can impact the efficiency and productivity of your production process. Consider factors such as size, capacity, speed, efficiency, quality, durability, and cost when selecting a machine that meets your business needs. By taking the time to research and evaluate different options, you can find a machine that will help streamline your production process and ensure that your milk powder cans are sealed securely and efficiently.

Maintenance Tips for Milk Powder Tin Can Cap Pressing Machine

Maintaining a milk powder tin can cap pressing machine is essential to ensure its optimal performance and longevity. Regular maintenance not only prevents breakdowns and costly repairs but also ensures that the machine operates efficiently, producing high-quality products consistently. In this article, we will discuss some key maintenance tips for a milk powder tin can cap pressing machine.

First and foremost, it is important to regularly clean the machine to prevent the buildup of dirt, dust, and other contaminants that can affect its performance. Use a soft cloth or brush to remove any debris from the machine’s exterior and interior components. Pay special attention to the cap pressing mechanism, as any residue or buildup can cause the machine to malfunction.

In addition to cleaning, lubricating the moving parts of the machine is crucial for smooth operation. Use a high-quality lubricant recommended by the manufacturer to ensure that the parts move freely and without friction. Be sure to follow the manufacturer’s guidelines on how often to lubricate the machine, as over-lubrication can be just as harmful as under-lubrication.

Regularly inspecting the machine for any signs of wear and tear is also important. Check for loose or damaged parts, such as belts, gears, and bearings, and replace them as needed. Keeping a spare parts kit on hand can help minimize downtime in case of a breakdown.

Calibrating the machine regularly is another key maintenance tip. Proper calibration ensures that the machine operates at the correct pressure and speed, resulting in consistent cap pressing. Follow the manufacturer’s instructions on how to calibrate the machine, and make any necessary adjustments as needed.

It is also important to monitor the machine’s performance regularly. Keep track of the number of cans processed, the speed of operation, and any issues or errors that arise during production. This information can help you identify any potential problems early on and take corrective action before they escalate.

Lastly, scheduling regular professional maintenance checks is essential for keeping your milk powder tin can cap pressing machine in top condition. A trained technician can inspect the machine thoroughly, identify any issues, and perform any necessary repairs or adjustments. Regular maintenance checks can help extend the life of the machine and prevent costly breakdowns.

In conclusion, proper maintenance is key to ensuring the optimal performance and longevity of a milk powder tin can cap pressing machine. By following these maintenance tips, you can keep your machine running smoothly and producing high-quality products consistently. Remember to clean, lubricate, inspect, calibrate, monitor, and schedule regular maintenance checks to keep your machine in top condition.