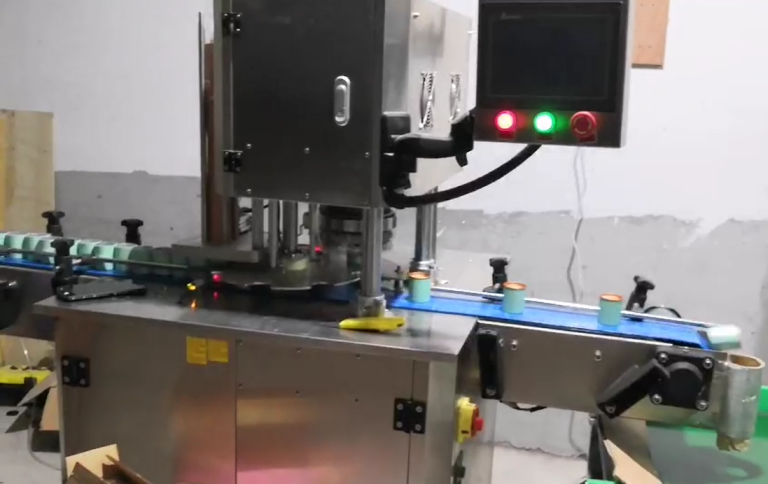

In the world of packaging, quality is of utmost importance. Semi-automatic can seamer machines have emerged as a vital tool in ensuring that packaging meets the highest standards.

These machines play a crucial role in creating a secure and tight seal on cans. A well-sealed can protects the contents from external elements such as air, moisture, and contaminants, which can significantly impact the quality and shelf life of the product inside.

The precision and consistency offered by semi-automatic can seamer machines are key factors in enhancing packaging quality. Every seal is executed with exactitude, reducing the likelihood of leaks or imperfect closures. This ensures that the contents remain fresh and intact throughout storage and transportation.

The materials used in the construction of these machines are of high quality, designed to withstand the rigors of continuous operation while maintaining their sealing performance. This durability contributes to long-term packaging quality.

Moreover, semi-automatic can seamer machines can be adjusted and calibrated to meet the specific requirements of different products and can sizes. This flexibility allows for customized packaging solutions that are tailored to the unique needs of each item, further enhancing the overall quality of the packaging.

The controlled and efficient process of these machines also helps minimize damage to the cans themselves, preserving their appearance and integrity.

In conclusion, semi-automatic can seamer machines are indispensable in the pursuit of superior packaging quality. Their ability to provide reliable, precise, and customizable sealing solutions makes them an essential component in the packaging industry, ensuring that products reach consumers in the best possible condition.