It seems we can’t find what you’re looking for. Perhaps searching can help.

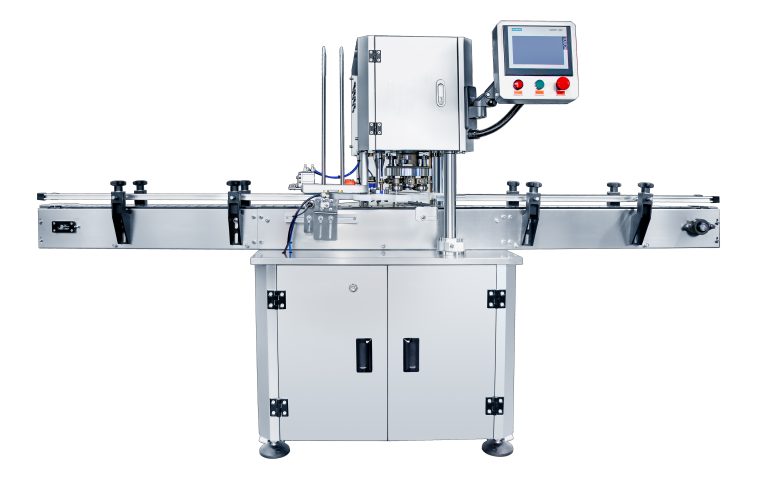

Can Sealing Machine Manufacturer: Why Our Can Sealing Machines The Best?

Superior Quality Materials Used in Our Can Sealing Machines When it comes to choosing a can sealing machine manufacturer, quality is of utmost importance. At our company, we take pride in the superior quality materials used in our can sealing machines. We understand the importance of durability and reliability in…