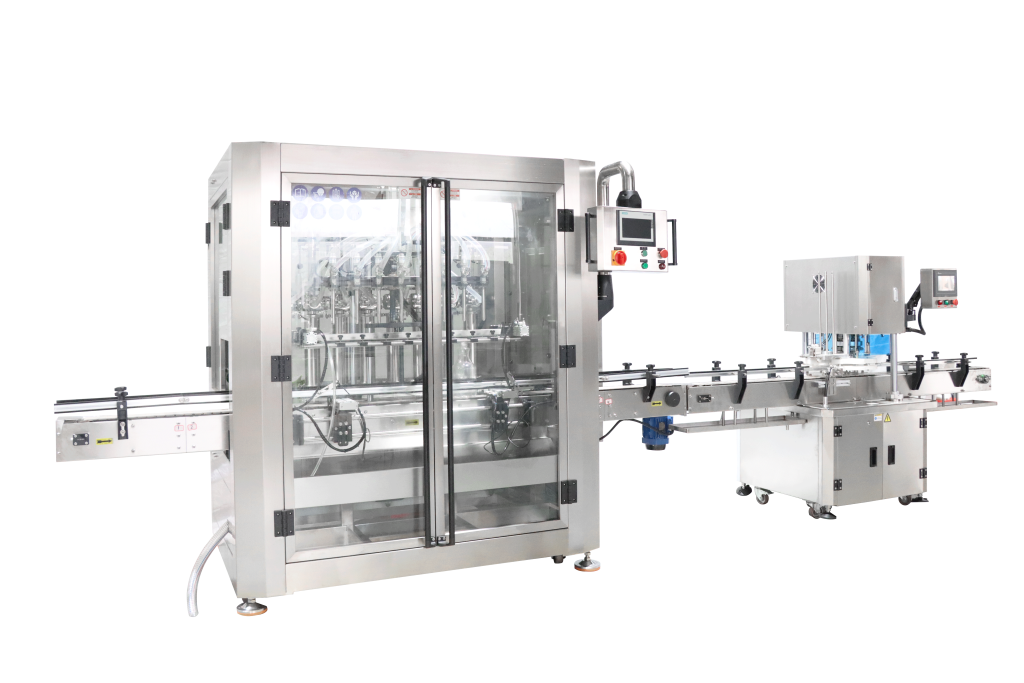

In the world of aluminum can packaging, the Automatic Liquid Filler Seamer Line is a game-changer.

This integrated system combines the functions of liquid filling and seam sealing in one seamless operation. The automatic nature of the line ensures consistent and precise filling of the liquid into each aluminum can, eliminating variations and minimizing waste.

One of the major advantages of this line is its high-speed performance. It can handle a large volume of cans in a short amount of time, meeting the demands of mass production. This rapid throughput helps businesses increase productivity and meet market deadlines.

The accuracy of the filling process is crucial. It precisely measures the liquid to the desired level, ensuring that each can contains the correct amount. The seamer then creates a tight and secure seal, preventing leaks and maintaining the integrity of the packaging.

The line is also highly configurable to accommodate different liquid viscosities and can sizes. This flexibility allows it to be used in a wide range of industries, from beverages to chemicals.

In addition, the Automatic Liquid Filler Seamer Line is equipped with advanced control systems and sensors that monitor the entire process. Any deviations or faults are detected immediately, allowing for quick adjustments and minimizing downtime.

The reliability and durability of the equipment ensure long-term performance with minimal maintenance requirements. This translates to lower operating costs and increased efficiency over time.

Overall, this Automatic Liquid Filler Seamer Line simplifies the packaging process, improves quality control, and boosts productivity, making it an essential component for any business that relies on aluminum can packaging.

Stay tuned to our blogs for more in-depth looks at the latest innovations in packaging technology!