Automatic powder auger fillers have emerged as a revolutionary force in transforming packaging lines for several compelling reasons.

Firstly, they bring an unprecedented level of efficiency and speed to the filling process. Their ability to fill containers at a rapid pace significantly boosts the overall productivity of the packaging line, allowing for higher output in less time.

The precision and accuracy they offer ensure that each container is filled with the exact amount of powder, eliminating variations and inconsistencies. This not only enhances the quality of the packaged products but also reduces the likelihood of customer complaints and returns.

The automated nature of these fillers minimizes the need for manual labor, reducing the potential for human error and fatigue. This leads to more reliable and consistent filling results, as well as a safer working environment.

They are highly adaptable and can handle a wide range of powder types and container sizes. This flexibility allows packaging lines to accommodate diverse products without the need for frequent equipment changes or adjustments.

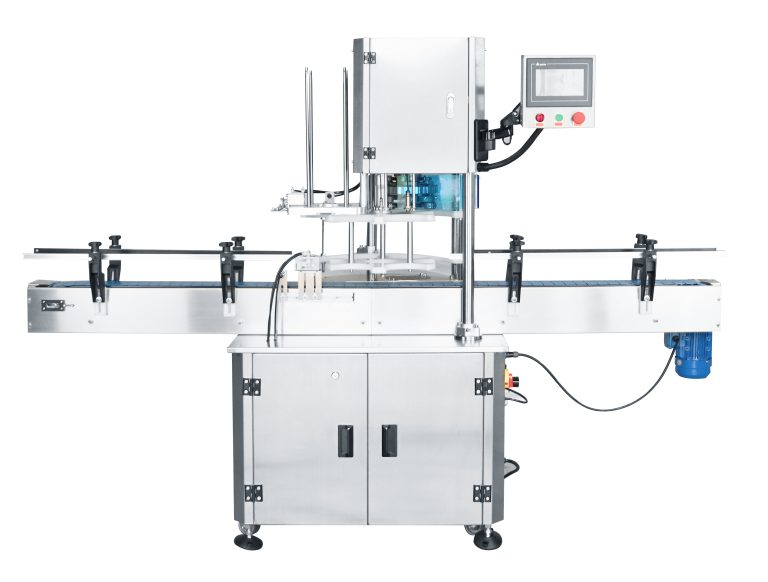

Automatic powder auger fillers can be seamlessly integrated with other packaging machinery, creating a synchronized and streamlined workflow. This integration optimizes the entire packaging process, reducing downtime and increasing operational efficiency.

Moreover, their advanced control systems provide real-time monitoring and data analytics, enabling operators to make informed decisions and promptly address any issues that arise.

In summary, automatic powder auger fillers have redefined the packaging line landscape by delivering enhanced productivity, quality, flexibility, and operational control, making them an indispensable component for modern packaging operations.